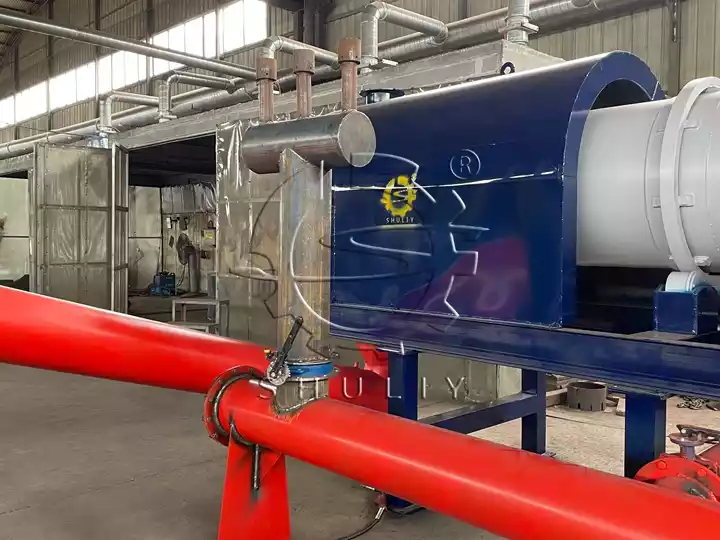

مؤخرًا، انتهى مصنعنا من إنتاج فرن تفحيم الفحم المستمر، والذي قمنا بشحنه إلى كوبا لمساعدة العملاء المحليين في تفحيم وإعادة استخدام موارد قشر الأرز.

العميل في هذه الشراكة هو شركة بارزة لمعالجة النفايات الزراعية ومقرها في كوبا. تركز هذه الشركة على تحويل النفايات الزراعية إلى منتجات قيمة لطاقة الكتلة الحيوية، بهدف تقليل الاعتماد على الوقود الأحفوري، وتقليل انبعاثات الكربون، وتعزيز التنمية المستدامة.

معلومات خلفية العميل

يتمتع العميل بعلاقات قوية وشبكة واسعة النطاق داخل القطاع الزراعي الكوبي، مع التركيز في المقام الأول على جمع النفايات الزراعية ومعالجتها وإعادة استخدامها.

يمثل قشر الأرز، وهو المنتج الثانوي الرئيسي لمعالجة الأرز، جزءًا كبيرًا من النفايات الزراعية في كوبا. لقد سعى العميل باستمرار إلى إيجاد طريقة فعالة وصديقة للبيئة لمعالجة قشر الأرز وتحويله إلى وقود الكتلة الحيوية الذي يحمل قيمة سوقية.

موقع تسليم وتركيب فرن تفحيم الفحم المستمر

وبعد إجراء فحوصات شاملة للجودة وتقييمات للأداء، تمت تعبئة فرن التفحم المستمر بدقة وتحميله على سفينة شحن متجهة إلى كوبا. وبعد عدة أسابيع في البحر، وصلت الآلة إلى الميناء الكوبي دون أي مشاكل.

سافر فريق من المهندسين على الفور إلى كوبا للمساعدة في تركيب الفرن والمشاركة في المناقشات والتدريبات الفنية التفصيلية. وقد قدموا شرحًا شاملاً لمبادئ العمل وأساليب التشغيل وإجراءات الصيانة لفرن الفحم، مما يضمن أن يتمكن الموظفون الكوبيون من تعلم كيفية تشغيل المعدات بأنفسهم بشكل فعال.

مع الجديد فرن تفحم الفحم المستمر الآن قيد التشغيل، يمكن للعميل تحويل كميات كبيرة من قشور الأرز بكفاءة إلى فحم ممتاز لوقود الكتلة الحيوية. ويمكن توفير هذا الفحم لكل من القطاعين الصناعي والسكني المحلي، ويمكن أيضًا تكريره إلى منتجات عالية الجودة مثل الفحم المنشط، وبالتالي تحسين استخدام موارد قشر الأرز.