Im Februar 2022 wurde die Produktionslinie für Shisha-Kohlebriketts nach Indonesien verkauft. Der Kunde möchte mit Kokosnussschalen viereckige Kohle herstellen. Wir haben dem Kunden eine komplette Shisha-Kohle-Produktionslinie vom Holzzerkleinern bis zur Kohle-Verpackung zur Verfügung gestellt. Nachfolgend finden Sie den Transaktionsprozess des Kunden.

Einführung der Shisha-Kohlebrikett-Produktionslinie in Indonesien

Der Kunde ist ein großes Zigarettenunternehmen in Indonesien, das Holzkohle als Wärmequelle für den Kessel während des Verarbeitungsprozesses produzieren möchte. Die Mitarbeiter der Einkaufsabteilung des Unternehmens, die direkt mit uns kommuniziert haben, werden den Preis ihrem Manager zur Entscheidungsfindung vorlegen. Zunächst haben wir uns nach den Rohstoffen erkundigt, die die Kunden verwenden, und dann die entsprechenden Maschinen des Unternehmens vorgestellt, indem wir die Produktionsbedürfnisse der Kunden verstanden haben. Durch die Kommunikation haben wir erfahren, dass der Kunde Kokosnussschalen verwenden möchte, um Holzkohle zu produzieren. Da die Beschreibung der Rohstoffe nicht klar war, hat der Kunde die Initiative ergriffen, uns die Rohstoffe zur Produktion zu senden.

Die Produktion der Wasserpfeifen-Kohle-Produktionslinie

Dann geht es darum, die von dem Kunden produzierte Holzkohle zu bestätigen. Der Kunde sagte, dass es das erste Mal ist, dass er Holzkohle produziert. Da der Kunde nicht sehr gut über die Holzkohleverarbeitungsindustrie informiert ist, stellen wir zunächst die Arten und Prozesse der Holzkohleproduktion vor. Nach zwei Tagen der Kommunikation hat der Kunde ein klares Verständnis für die Produktion von Holzkohle. Unsere Mindestproduktion beträgt 1 Tonne pro Tag, und die maximale Produktion beträgt 1 Tonne pro Stunde. Das Tabakunternehmen, in dem sich der indonesische Kunde befindet, ist sehr groß, aber da es sich um den ersten Import handelt, wählen wir eine mittlere und konstante Shisha-Holzkohlebrikett-Produktionslinie, die 4 Tonnen pro Tag produziert.

Details zur Shisha-Kohlebrikett-Produktionslinie, die Indonesien gekauft hat

| Artikel | Maschinenbild | Spezifikationen |

| Holzzerkleinerungsmaschine |  | Modell:600 Leistung:30kw Kapazität: 1000 kg pro Stunde Abmessungen:1,65*0,75*1,05m Gewicht: 600kg |

| Schneckenförderer |  | Abmessung: 4m*0.3m*0.5m Leistung: 4kw |

| Kontinuierlicher Kohlenstoffisierungsofen |  | Modell: SL-800 Abmessung: 9*2.6*2.9m Leistung:22kw Kapazität: 300 kg pro Stunde Gewicht: 9 t Dicke: 11 mm |

| Schneckenförderer |  | Abmessung: 4m*0.3m*0.5m Leistung: 4kw |

| Holzkohlezerkleinerungsmaschine |  | Modell: SL-600 Leistung: 22 kW Kapazität:500kg pro Stunde Endgröße: weniger als 5 mm Durchmesser des Zyklons: 1 m einschließlich Ventilator und 5 Beutel zur Staubentfernung |

| Luftschleuse |  | Leistung: 1,5 kW 18L |

| Schneckenförderer |  | Dimension: 4m*0,3m*0,5m Leistung: 4kw |

| Radmahlmaschine |  | Modell: 1300 Leistung: 5,5 kW Kapazität: 300-400 kg pro Stunde Innere Durchmesser: 1300mm Abmessung: 1350*1350*1400mm |

| Gurtförderer |  | Abmessung: 5m*0.7m*0.7m Leistung: 2,2 kW |

| Hydraulische Shisha-Kohlemaschine |  | Druck: 100 Tonnen Kapazität: 44 Stück pro Durchgang, 4 Mal pro Minute Gewicht: 2800 kg Hydraulikpumpe Leistung: 15 kW Hauptgerät Abmessungen: 1000*2100*2000 mm Förderleistung: 0,75 kW Entladung Leistung: 0,75 kW Entladeförderer: 800*850*1850 mm Größe des Steuerungsgehäuses: 530*900*1100 mm |

| Trocknungsmaschine |  | Abmessungen: 8,8*2,2*2,2 m Material: Farbstahl, 75 mm Steinwolleplatte Kapazität: 3 Tonnen Kohle pro Durchgang, benötigt 8-10 Stunden pro Durchgang. Biomasse als Wärmequelle verwenden. Biomassebrenner hinzufügen. |

Gründe, warum indonesische Kunden Shuliy wählen

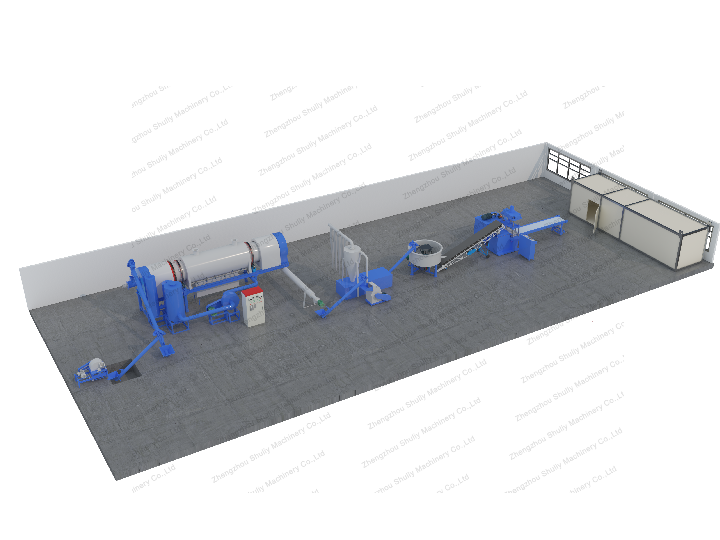

Zunächst einmal sind wir in der Lage, eine hochwertige Shisha-Kohlebrikett-Produktionslinie für indonesische Kunden bereitzustellen; zweitens haben wir nicht nur die Verwendung und Handhabung unserer Maschinen eingeführt, sondern auch den Produktionsprozess und die Fähigkeiten der Shisha-Kohle erklärt. Darüber hinaus haben wir ein sehr professionelles Team. Bei einer so großen Produktionslinie können wir aufgrund der großen Größe der Maschine keine Bilder und Videos der Maschinen verwenden, um den Arbeitsprozess der Maschine zu zeigen. Wir werden den Kunden ein 3D-Simulationsvideo zur Verfügung stellen, um klar zu zeigen, wie die Maschine verwendet wird.