Letzten Monat haben wir die Sägespänebrikettmaschine nach Kambodscha verschickt. Die Sägespänebrikettmaschine verwendet eine Maschine zur Formung von Holzspänen, um Holzspäne durch Erhitzen und Extrusion zu formen.

Rohstoffe, die in der Holzspäne-Brikettiermaschine verwendet werden.

Sperrholz ist ein häufig verwendetes Material für Dekoration oder Möbelproduktion. Bei der Herstellung von Sperrholz fallen viele Reste an. Die Verwendung der Sägemehlbrikettiermaschine erfordert zunächst das Zerkleinern, das Verarbeiten zu Holzspänen und dann das Brikettieren mit der Sägemehlbrikettiermaschine, um Brennstoff zu erzeugen, der relativ feuerfest und leicht zu transportieren ist.

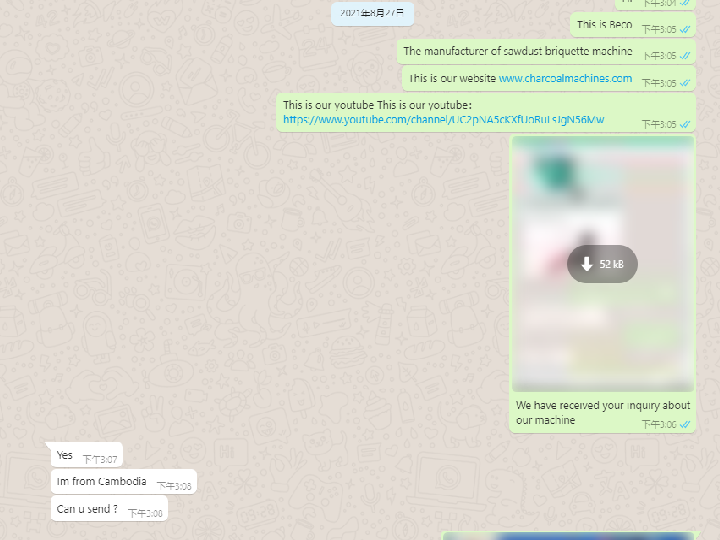

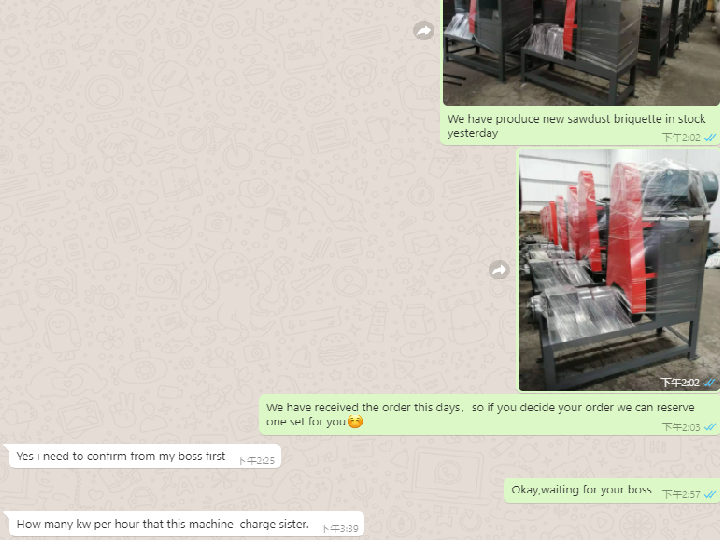

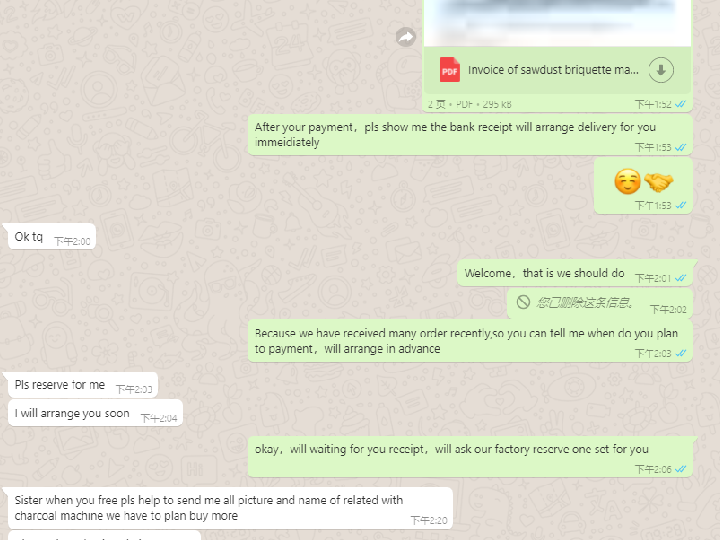

Kundenvorstellung der Sägemehl-Brikettmaschine in Kambodscha

Das Ziel unserer Zusammenarbeit diesmal ist ein Unternehmen zur Verarbeitung von Sperrholz. Sie haben ihre eigene Verarbeitungsfabrik mit einer sehr hohen Produktionskapazität. Viele Abfälle bei der Produktion von Sperrholz werden verschwendet, und der Kunde möchte diese Reste wiederverwenden. Daher möchten sie eine Stäbchenmaschine kaufen.

Welche Rohmaterialien kann die Holzbrikettiermaschine verwenden?

Es kann Sägemehl, Sägemehl, Reishülsen, Bagasse und Erntereste als Verarbeitungsrohstoffe verarbeiten. Nach dem Zerkleinern wird es durch eine Schraube erhitzt und zirkuliert und dann geformt. Die Größe beträgt in der Regel 50-80 cm, und es gibt Löcher in der Mitte, um das Brennen zu erleichtern.

Details zur Holzspäne-Brikettmaschine

Modell: SL-50

Kapazität: 250-300 kg/h

Leistung: 18,5 kW

Spannung: 380 V, 50 Hz, 3 Phasen

Verpackungsgröße: 1580*675*1625

Gewicht: 750 kg

Einführung in die Shuliy Firma

Shuli ist ein Außenhandelsunternehmen mit zehn Jahren Exporterfahrung. Die Holzkohleproduktionslinie des Unternehmens, Brikettmaschinen, Karbonisierungsofen und andere Produkte, wenn wir mit Kunden kommunizieren, konfigurieren wir geeignete Maschinen entsprechend den unterschiedlichen Produktionsmaterialien der Kunden, wie z. B. die Produktion von Rohstoffen und Kokosnussschalen, Altholz usw., müssen im Allgemeinen in den Rohstoffen zerkleinert, in Holzspäne umgewandelt und dann verarbeitet werden.