Hii tanuru ya kaboni ya makaa ni vifaa vikubwa vya kaboni. Ikilinganishwa na tanuru nyingine za kaboni, ina kazi yenye nguvu zaidi ya kaboni, anuwai pana ya vifaa vinavyoweza kukaboni, na uzalishaji wa kuendelea wenye ufanisi wa juu wa uzalishaji. Mashine hii ina uzalishaji mkubwa wa tani 3 kwa saa lakini pia ina mfano mdogo wa 500kg kwa saa.

Maskiner för att tillverka biokol används vanligast vid produktion av kol och ris-husk kol och används ofta i produktionen av hookah-kol och grillkol produktion. Dessutom är våra kolsyreförbränningsugnar så populära att de har skickats till följande länder som Tyskland, Iran, Japan och Malaysia.

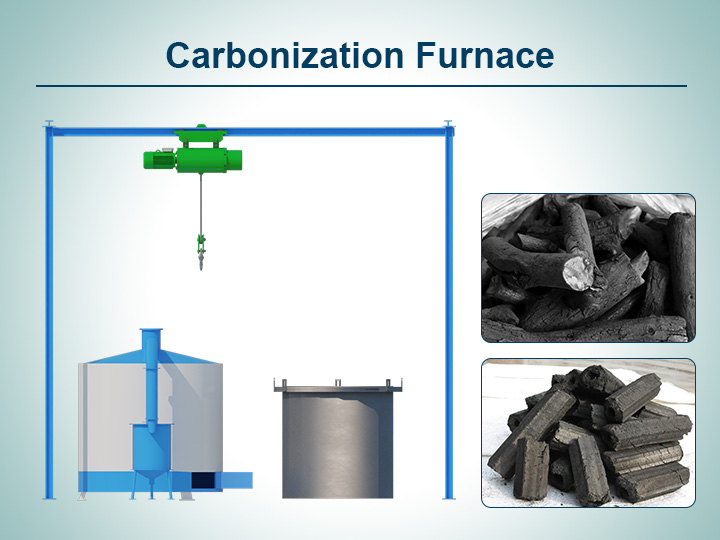

Aina nyingine mbili za tanuru za makaa ya mawe zilizonyeshwa katika video hapo juu (tanuru za kaboni za aina ya hoist zinazouzwa sana na tanuru za kuchoma za usawa) zimeorodheshwa hapa chini, ili uweze kuchagua kulingana na mahitaji yako.

Råvaror för kolkarboniseringsugn

Kwa tanuru hii ya kaboni, bidhaa zote zinazok含 kaboni zinaweza kuwa kaboni, hasa baadhi ya taka za jikoni, nguo za zamani, kinyesi cha wanyama, na hata mfinyanzi wa mto unaweza kuwa kaboni. Vifaa maalum vya kawaida ni pamoja na mabaki ya majani, makapi ya mchele, majani, vumbi la mbao, maganda ya punda, gome, unga wa mianzi, chips za mianzi, matawi, mizizi ya miti, ganda la nazi, mawe ya jujube, maganda, mifupa ya ng'ombe, kinyesi cha ng'ombe, nk.

Mashine ya kutengeneza mkaa wa biomass hali za usindikaji

Fuktigheten är under 25%. Om det finns för mycket fukt måste det torkas först. Materialets finhet är 20 mm. Om materialet är för stort måste det krossas först. Den allmänna kolsyre tiden är 18-20 minuter, och en sats kan kolsyresättas på cirka 20 minuter, och produktions effektiviteten är mycket hög.

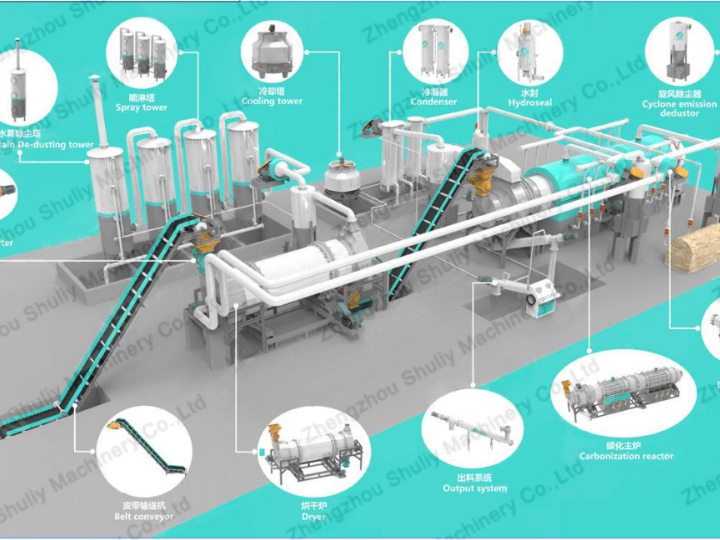

Struktur huvudsaklig för kolkarboniseringsugn

Muundo wa msingi wa mashine unajumuisha tanuru ya kaboni ya mkaa, tanuru ya gesi, mchakato wa mkaa, msafishaji wa gesi inayoweza kuwaka, na paneli ya kudhibiti nambari ya akili iliyoongezwa kwenye kibao chake.

Parametrar för tillverkning av biomassa kolmaskin

| Modell | SL-0812 | SL-1015 | SL-1218 | SL-1320 |

| Uwezo wa Kula kwa Saa | 500kg | 0.8-1 Tani | 1.5-2 Tani | 2.5-3 Tani |

| Mbinu ya Kazi | kuendelea kaboni | kuendelea kaboni | kuendelea kaboni | kuendelea kaboni |

| Ukubwa wa Reactor | 800mm | 1000mm | 1300mm | 1700mm |

| Värmematerial | Mkaa, kuni, dizeli, gesi asilia, LPG, pellets za biomass, nk. | Mkaa, kuni, dizeli, gesi asilia, LPG, pellets za biomass, nk. | Mkaa, kuni, dizeli, gesi asilia, LPG, pellets za biomass, nk. | Mkaa, kuni, dizeli, gesi asilia, LPG, pellets za biomass, nk. |

| Total effekt | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Yaliyomo ya Sakafu (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Shinikizo la Uendeshaji | Shinikizo la Kudumu | Shinikizo la Kudumu | Shinikizo la Kudumu | Shinikizo la Kudumu |

| Njia ya Kupoa | Kuhifadhi Maji ya Kupoa | Kuhifadhi Maji ya Kupoa | Kuhifadhi Maji ya Kupoa | Kuhifadhi Maji ya Kupoa |

Mashine hii ni kubwa zaidi, lakini pia kuna mifano tofauti, mfano mdogo zaidi ni SL-0812, ambayo inaweza kuzalisha 500kg, na mfano mkubwa zaidi ni SL-1320, ambayo inaweza kuzalisha 2.5-3Tani. Nyenzo zinaweza kutolewa mara moja baada ya uzalishaji, ambayo ni rahisi na yenye ufanisi.

Fördelar med kolkarboniseringsugn

Röklös karboniseringsdesign

Kwa kupitisha muundo mpya wa ubunifu, gesi ya moshi wa mwako inaweza kutolewa hadi kiwango kinachohitajika, na gesi ya moshi wa mwako inaweza kutumika kikamilifu ili kufikia kaboni isiyo na moshi wakati wa mchakato wa uendeshaji.

Kontinuerlig drift och storskalig produktion

Furuna ya kaboni ya kuendelea inashinda hasara za furuna za kaboni za jadi za kundi, na kupitia uvumbuzi, inaweza kufanya uzalishaji wa kuendelea kwa ufanisi. Furuna mpya ya kaboni ya Taida inategemea furuna ya kaboni ya ngoma na inasasishwa kwa mzunguko ili kuwasaidia watumiaji kufikia uzalishaji wa kiwango kikubwa.

Kipaumbele cha vifaa na dhamana ya maisha

Mfumo wa kuchoma unaoweza kuwaka unatumia kulehemu kwa masafa ya juu, na ganda la kupasha joto limepambwa na nyuzi za moto za juu, ambazo zina maisha marefu ya huduma na sehemu zinazovaa kwa kuchoma, ambayo inawafanya watumiaji wawe na wasiwasi kidogo.

Matumizi ya nishati ya chini na uzalishaji wa kijani

Mchakato wa uzalishaji wa uzalishaji wa kaboni/gasi/petroli unatekelezwa, na kasoro za jadi za matumizi makubwa ya nishati/mchafuzi mkubwa/ufanisi mdogo zinatatuliwa. Katika mchakato wa kaboni, tar/viniga vya mkaa na gesi inayoweza kuwaka zote zinakusanywa na kutumika tena.

Mifano ya mafanikio ya mpango wa kubuni wa tanuru ya kaboni ya Shuliy

Efter att ha lärt sig om behoven hos iranska kunder att kolsyra slam, hjälpte Shuliy Company kunderna att göra en genomförbar plan, inklusive avvattning av slam, torkning av slam och kolsyra av slam. Det kolsyra slammet kan användas för jordförbättring, bearbetning och produktion av fyllnadsmaterial och byggnation, etc., den största fördelen med denna kolsyrautrustning är mångfalden av produkter som kan kolsyra.

Hur använder man karboniseringsutrustning för att göra vinster

Bidhaa za kaboni zinaweza kuuzwa moja kwa moja hivyo uwekezaji wa uzalishaji ni mdogo na kurudi kwa gharama ni haraka. Aidha, zinaweza kushughulikiwa zaidi baada ya kaboni, kama vile kushughulikia kuwa makaa ya moshi na makaa ya barbecue. Bidhaa zilizoshughulikiwa kwa kina zina faida kubwa.

Eftersom tanuru ya kaboni ndiyo msingi wa uzalishaji wa bidhaa za kaboni, kiasi cha mauzo ya tanuru ya kaboni daima kimekuwa bidhaa nyota ya Shuliy Machinery Co., Ltd. Karibu kutazama na kujifunza zaidi kuhusu teknolojia yetu ya tanuru ya kaboni ya mkaa, na usisite kuwasiliana nasi kwa maelezo zaidi!