Chipper ya kuni ya ngoma inaweza kukata mbao, matawi, bodi, mianzi, maganda ya pamba, na malighafi nyingine za nyuzi za kuni au zisizo za kuni kuwa vipande vya kiwango sawa (20-40mm kwa urefu, 3-5mm kwa unene), ikiwa na kiwango cha uthibitisho cha zaidi ya 97%. Inatumika sana katika viwanda vya karatasi, viwanda vya bodi za chembe, viwanda vya bodi za nyuzi za kati na za juu, mitambo ya nguvu ya biomass, vituo vya kuuza chip za kuni, na kadhalika.

Fördelar med träflismaskin

- Stark anpassningsförmåga: den kan installeras och användas i olika geografiska miljöer och klimatförhållanden utan att påverkas av årstider.

- Ingen grundinstallation: utrustningen kan sättas i bruk inom 1-2 dagar efter ankomst, vilket sparar 10-15 dagar.

- Kostnadsbesparing: ingen grundkonstruktion kan spara användare cirka 500-2000 dollar i arbets- och materialkostnader (beroende på modell).

- Flexibel och bekväm installation: ingen behov av att fixa installationsplatsen, enkel justering, förbättrar utrustningens flexibilitet och rörlighet.

- Rikta utmatning: utrustad med en andra utmatningsanordning kan utmatningsriktningen justeras flexibelt efter behov.

- Stort utbyte: daglig bearbetningskapacitet på 30-300 ton, för att anpassa sig till olika användares produktionsbehov.

- Enkel drift: rimlig strukturell design, enkel drift och underhåll, lämplig för alla typer av användare.

Huvudstruktur för träflisningsmaskin

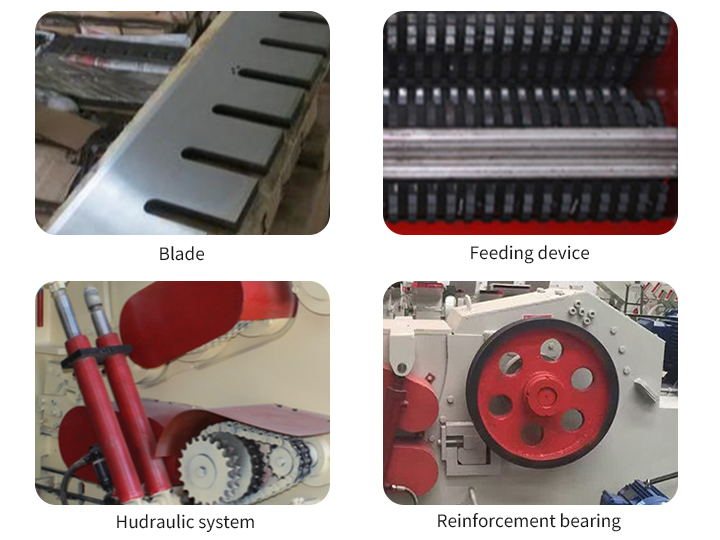

Mashine ya kukata kuni ya ngoma inajumuisha chuma cha nguvu ya juu kilichounganishwa, mfumo wa zana za kukata, roller za kulisha za juu na chini, ukanda wa kusafirisha, ingizo na kutoa, motor, na mfumo wa hidroliki.

Med en robust struktur, smidig drift och synergistiskt samarbete mellan alla delar kan den effektivt genomföra träflisningsoperationen och är lämplig för en mängd olika arbetsförhållanden.

Arbetsprincip för trumträds kross

Mashine ya kukata kuni inatekeleza mabadiliko kutoka kwa malighafi hadi chips za kuni zilizopangwa katika hatua tatu, kwa ufanisi mkubwa na matumizi ya nishati yaliyodhibitiwa:

Ushindishaji wa kulisha kwa nguvu ya maji

- Råmaterialet matas genom ett brett transportband, och det hydrauliska systemet med dubbelrulle komprimerar och för materialet framåt automatiskt med en jämn hastighet.

- Att övervinna motståndet mot deformation av grenarna säkerställer stabiliteten i den kontinuerliga matningen.

- Intelligent justerbart rulltryckgap, lämpligt för alla typer av råmaterial med diameter ≤ 350 mm.

Kukata kwa nguvu kwa vilemba vingi

- Kärnknivtrumman integrerar en högstyrkelegering flygande knivuppsättning, som roterar med en hög hastighet av 960 varv per minut.

- Bladet har en radial spiral-layout, som fäster vid råmaterialets yta under hela skärprocessen.

- Låg motståndslager-slicing uppnås, vilket signifikant minskar spåntalen och förlänger verktygets livslängd.

Matokeo ya kupanga kwa kimbunga

- Kukatwa mbao chips hupenya kupitia mashimo ya skrini ya drum ya kisu na kusafirishwa kwa mwelekeo na hewa ya shinikizo hasi ya kasi kubwa inayozalishwa na impela ya kisu.

- Den inbyggda graderingsskärmen separerar automatiskt de överdimensionerade spånen, och de kvalificerade spånen matas ut rent genom den slutna luftkanalen.

- Impurities hurumishwa kurudi kwenye eneo la kusaga kwa ajili ya usindikaji wa pili ili kuhakikisha kuwa kipande kilichokamilishwa kina kipenyo sahihi na kinakidhi viwango (±1mm makosa).

Mitambo ya kukata miti inaweza kupondwa zaidi kuwa vipande vya mbao kwa kuongeza masafa ya nyundo ya mbao nyuma ya mashine, na kisha kutumika kwa utengenezaji wa makaa na shughuli zingine.

Färdig produkt du kan få

Bidhaa iliyokamilishwa inayozalishwa na mashine hii ya kukata mbao ina saizi sawa ya chembe, muundo mzuri, na uso laini, ambayo inaweza kutumika kwa wingi katika uhandisi wa mbao, utengenezaji wa karatasi, na nyanja nyingine.

Trumvedsklipparens parametrar

| Modell | SL215 | SL216 | SL218 | SL2113 |

| Storlek på råmaterial(mm) | 160*400 | 230*500 | 300*680 | 450*700 |

| Antal knivar (stycken) | 2 | 2 | 2 | 2 |

| Knivens rotationshastighet(rpm) | 592 | 590 | 650 | 500 |

| Diameter ya malighafi (mm) | 160 | 230 | 300 | 450 |

| Ukubwa wa chipsi za mti (mm) | 30 | 30 | 30 | 38 |

| Uwezo (t) | 3-4 | 7-8 | 12-15 | 15-30 |

| Nguvu ya motor kuu (kw) | 45 | 55 | 110 | 200-250 |

| Nguvu ya motor ya roller ya kulisha (kw) | 2.2-3 | 3-4 | 4-5 | 7.5*2 |

| Effekt på oljepumpmotor (kw) | 1.5*1 | 1.5*1 | 1.5*1 | 3*1 |

| Maskinvikt (kg) | 3590 | 5030 | 7000 | 11840 |

| Maskinstorlek (mm) | 1470*1550*970 | 1800*1900*1210 | 2200*2150*1500 | 3670*2517*2050 |

| Effekt på transportörmotor (kw) | 3 | 3 | 3 | 3 |

Tack för att du läste om flismaskinen. Om du är intresserad av våra maskiner eller har några frågor, tveka inte att kontakta oss. Du kan berätta för oss om specifika krav innan du beställer en flismaskin. För att skydda våra kunders intressen kommer vi att välja den mest lämpliga maskinen för dig. Alla kunder som är intresserade av våra maskiner är också välkomna att besöka vår fabrik. Vi ser fram emot att etablera en samarbetsrelation med dig.