Furnace karbonisasi berkelanjutan tanpa asap adalah produk ramah lingkungan baru yang dikembangkan oleh perusahaan kami. Utamanya menggunakan teknologi karbonisasi distilasi kering, dalam peralatan tertutup suhu tinggi, air, asam asetat kayu, dan tar kayu dalam bahan baku diuapkan, dan kemudian sistem pemurnian gas buang digunakan untuk menjadikannya sebagai sumber panas utama selama karbonisasi. Selama seluruh proses, tidak ada asap, ramah lingkungan, dan tidak ada pembuangan limbah. Peralatan menyesuaikan suhu karbonisasi melalui kabinet kontrol PLC, kualitas karbonisasi stabil, tidak ada sudut mati, operasinya sederhana, nyaman, dan mudah dipelajari. Selain itu, sesuai dengan permintaan pasar, perusahaan kami dilengkapi dengan gasifier biomassa yang dikembangkan sendiri, yang memiliki struktur desain yang wajar, kegunaan yang kuat, dan efisiensi produksi gas yang tinggi. Hal yang penting adalah memulihkan gas buang, yang memiliki efek perlindungan lingkungan yang baik.

Pengenalan tungku karbonisasi kontinu tanpa asap

Furnace karbonisasi berkelanjutan tanpa asap adalah produk khusus yang mengubah berbagai pupuk biomassa menjadi karbon buatan mesin. Ini cocok untuk karbonisasi bahan baku kecil seperti serbuk gergaji, sekam padi, kulit buah, serpihan bambu, jamur, dan biomassa yang dihancurkan. Bubuk arang memiliki kandungan karbon tinggi, menjaga keadaan asli tanpa kerusakan, peng喂an berkelanjutan, dan arang berkelanjutan; furnace karbonisasi berkelanjutan tanpa asap adalah peralatan karbonisasi untuk memproses arang mentah, arang buatan mesin, dan blok arang tempurung kelapa. Ini cocok untuk tongkat bahan bakar buatan mesin, balok kayu, karbonisasi bahan baku besar seperti sekam kelapa, balok kayu, kacang pinus, jerami, dll., penggunaan berkelanjutan, waktu karbonisasi singkat, output karbonisasi tinggi, dan kualitas produk yang baik.

Gas buang yang dihasilkan selama proses karbonisasi dari tungku karbonisasi kontinu tanpa asap sepenuhnya dipulihkan, dan gas yang dapat terbakar yang dihasilkan mengalami pembakaran sekunder melalui proses penyemprotan, pendinginan, dan pemurnian. Berputar dalam cara ini, menggunakan gas yang dapat terbakar yang dihasilkan oleh diri sendiri untuk membakar diri sendiri, dan mencapai efek penghematan energi.

Peralatan yang termasuk dalam tungku karbonisasi kontinu tanpa asap

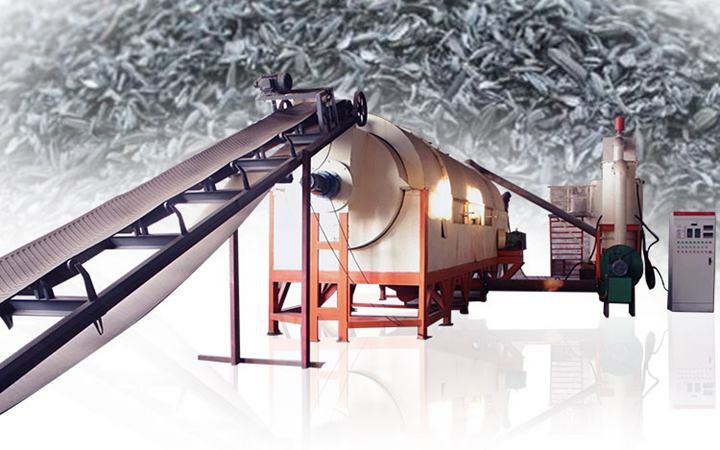

Furnace karbonisasi berkelanjutan tanpa asap mengadopsi proses karbonisasi yang ramah lingkungan dan tanpa asap yang wajar dan merupakan jenis baru peralatan karbonisasi cepat yang hemat energi. Mengadopsi proses karbonisasi perlindungan lingkungan tanpa asap yang wajar, seluruh set peralatan mencakup:

- Satu set peralatan terdiri dari sistem gasifikasi (tungku gasifikasi, menara semprot, pengumpul debu);

- Sistem pemurnian (menara semprot, pemisah minyak-air, filter);

- Sistem karbonisasi (host karbonisasi, pengumpan sekrup, pengumpan sekrup, pembuang pendingin, konveyor, bin pendingin produk jadi);

- Sistem kontrol (lemari kontrol).

Furnace karbonisasi kontinu tanpa asap

Fitur tungku karbonisasi kontinu tanpa asap

Furnace karbonisasi tanpa asap mengadopsi teknologi canggih untuk pemulihan, pemurnian, dan pembakaran sirkular gas-gas yang dapat terbakar seperti karbon monoksida, metana, dan oksigen yang dihasilkan selama proses karbonisasi. Ini tidak hanya menyelesaikan masalah pencemaran lingkungan yang disebabkan oleh asap tebal yang dihasilkan oleh furnace karbonisasi biasa selama proses karbonisasi, tetapi juga menyelesaikan masalah energi panas yang dibutuhkan oleh peralatan mesin arang, sepenuhnya mencapai swasembada, dan meningkatkan kontinuitas, ekonomi, dan pemanfaatan penuh peralatan. Sisa-sisa pertanian dan kehutanan mengubah limbah menjadi harta, mengurangi ketegangan antara pasokan dan permintaan sumber daya kehutanan di negara saya, dan memberikan kontribusi lebih untuk penghijauan lingkungan. Gas buang yang dihasilkan dalam proses furnace karbonisasi tanpa asap kemudian disemprot, didinginkan, dimurnikan, dan melalui proses lainnya, sehingga gas yang dihasilkan mengalami pembakaran sekunder. Berputar dengan cara ini, menggunakan panas yang dihasilkan oleh tubuh untuk membakar tubuh, dan mencapai efek penghematan energi. Selain itu, setelah gas buang dimurnikan dalam pipa, tidak ada gas buang di lingkungan produksi, yang ramah lingkungan dan memenuhi standar pembuangan gas buang nasional.

Furnace karbonisasi kontinu tanpa asap khusus dalam memproses bahan biomassa limbah. Perusahaan kami berkomitmen untuk membangun furnace karbonisasi kontinu tanpa asap yang profesional dengan peralatan karbonisasi yang masuk akal, nyaman, hemat tenaga, aman, ideal, luas, dan ekonomis. Bahan yang dapat dikarbonisasi oleh furnace karbonisasi kontinu tanpa asap adalah bahan biomassa. Biomassa padat dari peralatan ini memiliki sifat pembakaran melalui pemecahan termal tidak langsung pada suhu yang dapat dikendalikan untuk membentuk peralatan karbonisasi kontinu untuk karbon biomassa. Otomatisasi penuh dari furnace karbonisasi kontinu tanpa asap secara bertahap telah menggantikan tenaga kerja, sumber daya material, dan tenaga kerja, menghemat biaya dan secara signifikan meningkatkan efisiensi produksi. Seluruh proses karbonisasi adalah produksi otomatis, dengan operasi yang sederhana, menghemat waktu dan tenaga.