A máquina de carvão em favo de mel é feita de carvão em pó de ferro processado/carvão bruto (diâmetro <1mm), que é misturado e comprimido para fazer briquete de carvão. Os buracos na superfície do produto acabado facilitam a queima completa e reduzem o desperdício de energia. Após muitas melhorias, nossa máquina de briquete de carvão em favo de mel possui as vantagens de estrutura razoável, alta densidade dos produtos acabados, desempenho superior e longa vida útil.

Alternativamente, você pode escolher entre outros tipos de máquinas moldadoras de briquetes de carvão, incluindo Máquina de fabricação de briquetes de carvão | Extrusora de briquetes de carvão, e Máquina de briquetes de bola de carvão | Máquina de prensa de carvão para churrasco.

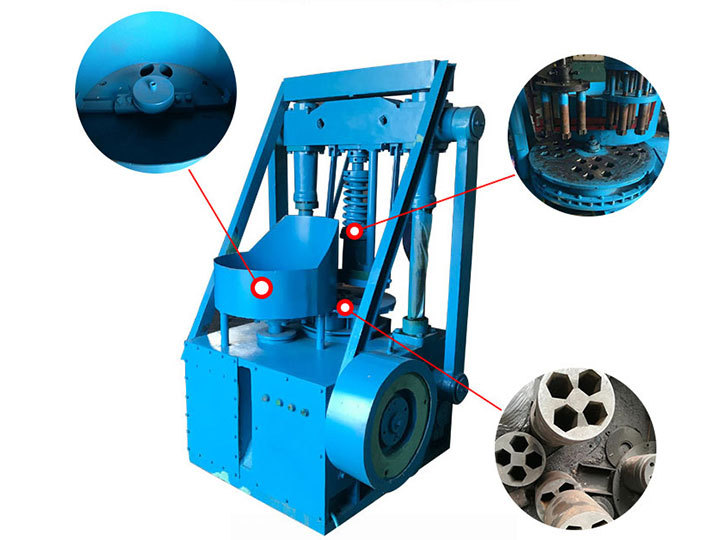

Estrutura e princípio da máquina de carvão em colmeia

A máquina de carvão em favo de mel tem uma estrutura simples e é dividida em cinco partes: um corpo, uma rotação, uma alimentação, uma estampagem e uma transmissão. As partes trabalham juntas e a operação é coordenada e estável.

- A parte do corpo: consiste em uma placa e uma base de máquina, que estão abertas para o esqueleto da máquina de carvão em favo de mel.

- Parte de transmissão: Consiste no motor, polia, engrenagem, eixo de transmissão e outros componentes. O motor gira o eixo da engrenagem através da polia e o transmite para o eixo de transmissão através de duas engrenagens. O par de engrenagens cônicas e o eixo rotativo acionam o mostrador, e o mostrador é girado para se mover para o disco de quatro furos.

- Parte de alimentação: Consiste em um eixo rotativo, um funil e um misturador. É acionado por uma engrenagem axial para misturar o carvão e misturá-lo no molde.

- Parte de estampagem: A parte de estampagem consiste principalmente em quatro barras deslizantes, uma viga deslizante, uma barra de perfuração, uma base de perfuração, uma cabeça de perfuração, uma placa de pressão móvel, um fundo de molde móvel e uma mola. Quando a máquina gira, as duas engrenagens giram através da barra de puxar para acionar a viga deslizante. Quando o punção desce, o punção é forçado a se mover para baixo, a placa móvel se move para cima e a mola é tensionada, o carvão é pressionado e o carvão é perfurado, e o carvão formado fica solto, pela mola. Pressione a placa ativa para determinar a compressão do carvão.

- Parte de transporte: A parte de transporte é composta por uma estrutura de transportador, uma polia, um suporte e uma correia transportadora. A correia transportadora é girada aleatoriamente para enviar o carvão moldado para fora do corpo, e o parafuso ajustável no transportador pode ajustar a tensão da correia transportadora.

Os requisitos de pó de carvão para a máquina de briquete de carvão

Quando a máquina de carvão em favo de mel está comprimindo o pó de carvão, se os grumos de carvão pulverizado forem muito grandes, precisamos triturar o carvão primeiro antes de pressionar. Ao mesmo tempo, uma certa quantidade de aglutinante geralmente é adicionada ao usar briquetes para pressionar o pó de carbono, para alcançar um melhor efeito de moldagem.

Isso ocorre porque, quando o teor de umidade do pó de carvão é alto, não é fácil de formar. E o pó de carvão e o pó de carvão vegetal devem ter propriedades de ligação adequadas, caso contrário, o pó de carvão e o pó de carvão vegetal devem ser processados. De dez a vinte por cento do carvão aglomerado pode ser misturado aos materiais-prima para aumentar suas propriedades de ligação.

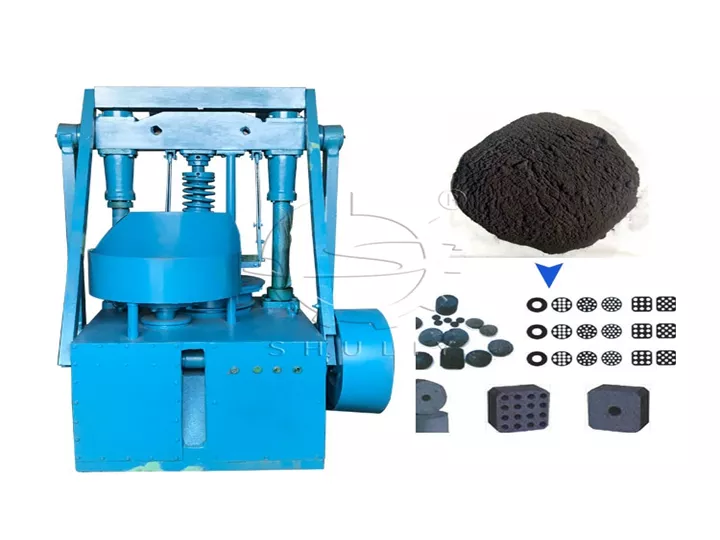

Moldes para fazer briquetes de carvão com diferentes formas

Para realizar a função multipropósito de uma máquina, podemos substituir o molde de extrusão da máquina de briquetes para fazer briquetes de diferentes formas. Normalmente, os briquetes de carvão em forma de favo de mel são cilíndricos com furos, e o número e o diâmetro dos furos podem ser personalizados.

Além disso, ao trocar diferentes moldes, a máquina de carvão em favo de mel também pode produzir prismas quadrangulares com furos e briquetes de carvão hexagonais com furos. Claro, o número e o diâmetro dos furos também podem ser personalizados.

Forma: Máquina formadora de briquetes de pó de carvão em favo de mel A forma de um briquete pode ser redonda, cilíndrica, quadrada, retangular, poligonal, hexagonal, em leque e muitos outros tipos, ou você pode ter sua forma ideal, podemos ajudá-lo a atender às suas necessidades.

Tamanho: O tamanho final de acordo com a forma e o molde da máquina, também pode ser decidido dentro de uma certa faixa.

Características: Briquetagem de exportação com alta densidade, inflamável, longo tempo de queima, não tóxico, sem fumaça e outras vantagens.

Principais características da máquina de fazer briquetes de carvão

- A máquina de carvão em forma de favo de mel funciona de forma eficiente e a produção é grande.

- Esta máquina tem um baixo consumo de energia e é amiga do meio ambiente.

- O molde está completo e pode ser trocado facilmente.

- As briquetes de carvão produzidas pela nossa máquina de moldagem de briquetes de pó de carvão em favo de mel não contêm aditivos químicos ou odores e são sem fumaça, não tóxicas ou combustíveis, portanto, é um equipamento de moldagem de carvão que economiza energia e protege o meio ambiente.

Lista de parâmetros da máquina de briquetagem de carvão em forma de favo de mel

A máquina de carvão em favo de mel é um equipamento de produção de alta eficiência e tecnologia avançada, o poderoso sistema de pressão e os moldes projetados com precisão garantem a densidade uniforme e a excelente qualidade do carvão em favo de mel. Seu desempenho excepcional, confiabilidade, economia de energia e proteção ambiental oferecem soluções de produção confiáveis e avançadas para a indústria de processamento de carvão.

| Modelo | Potência | Capacidade | Peso |

| SL-120 | 4.5kw | 6000Pcs/hora | 1.4t |

| SL-140 | 7.5kw | 8000Pcs/hora | 1.5t |

| SL-160 | 11kw | 10800Pcs/hora | 2t |

| SL-220 | 11kw | 13500Pcs/hora | 3,8t |

Vídeo de funcionamento da máquina de fazer briquetes de carvão

Obrigado pelo seu interesse em nossa tecnologia avançada de máquinas de carvão em favo de mel. Se você estiver interessado em nossa exibição de produtos e ansioso para explorar mais detalhes, não hesite em entrar em contato com nossa equipe profissional a qualquer momento. Nós forneceremos informações detalhadas e responderemos suas preocupações para garantir que você tome uma decisão sábia. Enquanto isso, convidamos sinceramente você a visitar nossa fábrica para proporcionar uma experiência visual e permitir que você tenha uma compreensão mais abrangente de nossa força técnica e qualidade de produto.