Die Kasten-Trocknungsmaschinen für Holzkohlebriketts werden häufig bei der Produktion und Verarbeitung von Holzkohle und verschiedenen Arten von geformter Holzkohle eingesetzt. Diese Ausrüstung erzielt effiziente, energiesparende und umweltfreundliche Trocknungsergebnisse durch wissenschaftliche Temperatur- und Feuchtigkeitskontrolle. Sie kann Produkte schnell und gleichmäßig trocknen, ohne die Form der Holzkohle zu beschädigen.

Neben der Holzkohletrocknung kann sie auch weit verbreitet für die Trocknungsbedürfnisse verschiedener Industrien wie Lebensmittel, Kräuter, Pflanzen und Fleisch eingesetzt werden, was sie zu einem wirklich multifunktionalen intelligenten und umweltfreundlichen Gerät macht.

Nach Markttests hat sich der Kasten-Trocknungsraum in Ländern wie Iran, Südafrika, Nigeria und den Philippinen großer Beliebtheit erfreut und zahlreichen Holzkohleproduzenten erhebliche wirtschaftliche Vorteile gebracht.

Rohmaterialien für die Holzkohlebrikett-Trocknungsmaschine

- Holzkohle: Shisha-Holzkohle, Grillholzkohle, Holzkohle-Sticks usw.

- Lebensmittel: Obst, Fleisch, Kräuter, Pflanzen und andere Produkte, die getrocknet oder dehydriert werden müssen.

- Anwendungen in mehreren Industrien: geeignet für fast alle Materialien, die getrocknet und entfeuchtet werden müssen, mit vielfältigen Funktionen.

Vorteile des Kasten-Trocknungsraums

- Hochwertige Materialien: Hergestellt aus 304 Edelstahl, ist es feuchtigkeitsbeständig, korrosionsbeständig, robust und langlebig.

- Sicher und zuverlässig: Die elektrische Trennungstechnologie verhindert Risiken wie Stromleckagen, Brände und Explosionen und gewährleistet die Betriebssicherheit.

- Gleichmäßige Trocknung: Das interne Design hat keine toten Winkel, wodurch sichergestellt wird, dass die Materialien gleichmäßig erhitzt werden und kein Teil ungetrocknet bleibt.

- Einfache Installation: Das kompakte Design ermöglicht die Installation im Innen- oder Außenbereich und bietet flexible Bedienung.

- Umweltfreundlich und schadstofffrei: Keine offenen Flammen oder Rauchemissionen, entspricht den Lebensmittelhygienestandards und ist somit ein grünes und nachhaltiges Produkt.

- Hochintelligent: Das mikrocomputergesteuerte intelligente System ermöglicht einen 24-Stunden-Dauerbetrieb ohne manuelle Überwachung und schaltet sich bei Erreichen der gewünschten Temperatur automatisch ab, um Energie zu sparen.

- Breites Anwendungsspektrum: Nicht nur für Holzkohle geeignet, sondern erfüllt auch die Trocknungsbedürfnisse verschiedener Branchen wie Lebensmittel, Kräuter und landwirtschaftliche Nebenprodukte.

Aufbau der Shisha-Kohlen-Trocknungsmaschine

Holzkohle-Trocknungs- und Entfeuchtungseinheit (einstellbare Temperatur im Trocknungsraum: 20℃-75℃, einstellbare Luftfeuchtigkeit: 5%-95%)

Mit einem Wagen ist der Wagen bequem für die Trocknung und den Kurzstreckentransport von getrockneter Holzkohle.

Die Wärmedämmbox besteht aus 4 mm dicken Farbstahlplatten für die Holzkohletrocknung, und dazwischen ist 7 mm dicke Steinwolle-Wärmedämmung eingebettet.

Sie kann die Außenseite der Brikett-Trocknungsmaschine für Holzkohle auf Raumtemperatur halten, Verbrennungen vermeiden und gleichzeitig sicherstellen, dass die Innentemperatur der Maschine nicht ansteigt.

Heißluftzirkulationsteil. Das Heißluftzirkulationssystem sorgt für eine gleichmäßige Erwärmung der Shisha-Holzkohlebrikett-Trocknungsmaschine, sodass auch die Kanten und Ecken der Holzkohle trocknen.

Die Heizmethode des BBQ-Kohlen-Trockners

Die Kasten-Trocknungsmaschine für Holzkohlebriketts unterstützt mehrere Heizmethoden und kann flexibel nach Kundenwunsch angepasst werden. Gängige Heizmethoden sind:

- Elektroheizung: sauber und umweltfreundlich, geeignet für Orte mit hohen Umweltschutzanforderungen.

- Gasheizung: schnelle Erwärmung, moderate Betriebskosten.

- Brennstoffheizung: geeignet für Gebiete mit bequemer Energieversorgung und ausreichender Wärme.

- Kohleheizung: traditionelle Methode, geeignet für einige Benutzer mit hohen Kostenanforderungen.

Basierend auf den tatsächlichen Nutzungsbedingungen des Kunden kann der Hersteller eine personalisierte Konstruktion und Anpassung anbieten, um eine bequemere Bedienung und eine energieeffizientere Leistung zu gewährleisten.

Wie funktioniert ein Shisha-Holzkohletrockner?

Nach der Formgebung enthalten Shisha-Holzkohle oder Grillholzkohle einen hohen Feuchtigkeitsgehalt (ca. 40 %) und müssen getrocknet werden, um ihre Form zu fixieren.

Der Kasten-Trocknungsraum verfügt über eine vollständig geschlossene Struktur und nutzt ein Heißluftzirkulationssystem, um die Wärme gleichmäßig in der Kammer zu verteilen, wodurch die Trocknungszeit verkürzt und konsistente Trocknungsergebnisse erzielt werden. Unter normalen Bedingungen kann der Feuchtigkeitsgehalt des Materials innerhalb von 7–8 Stunden von 40 % auf etwa 8 % reduziert werden.

Der Betriebsprozess ist einfach:

- Legen Sie die zu trocknenden Holzkohleblöcke auf den Wagenrost.

- Schieben Sie den Wagen in die Trocknungskammer.

- Stellen Sie die Trocknungszeit und -temperatur ein und starten Sie dann das Gerät.

- Sobald die eingestellte Zeit erreicht ist, stoppt das Gerät automatisch und die getrockneten und geformten Holzkohleblöcke können entnommen werden.

Video der Brikett-Trocknungsmaschine für Holzkohle

Modelle und Parameter der Holzkohlebrikett-Trocknungsmaschine

| Modell | Abmessungen (mm) | Anzahl der Heißluftventilatoren (1 Satz/0,58KW) | Anzahl der Feuchtigkeitsentzugventilatoren (1 Satz / 0,12 kW) | Saugzugventilator (1 Satz/0,37KW) | Trocknungswagen (Gruppe) | Trocknungsmenge (jedes Mal/kg) |

| SL-2 | 4000*1600*2500 | 4 | 2 | 1 | 2 | 600 |

| SL-4 | 6000*1600*2500 | 4 | 2 | 1 | 4 | 1200 |

| SL-6 | 7200*2300*2500 | 6 | 2 | 1 | 6 | 1800 |

| SL-8 | 8800*2300*2500 | 6 | 2 | 1 | 8 | 2400 |

Derzeit verfügt das Unternehmen Shuliy über vier Trocknungsboxen für Holzkohle, die Ausbringung jeder Trocknung beträgt 600 kg bis 2400 kg. SL-2 ist die kleinste Maschine, die jeweils 600 kg trocknet; 2 bedeutet, dass dieser Trockner zwei Wagen hat. Die Größe des Modells in der Tabelle ist nach der Anzahl der Wagen benannt; der größte Trockner ist SL-8, der jeweils 2400 kg trocknen kann und 8 Wagen hat.

Fazit

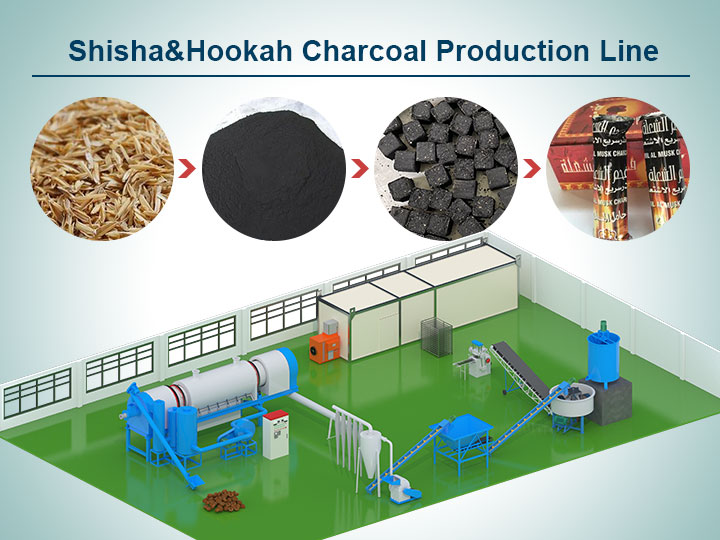

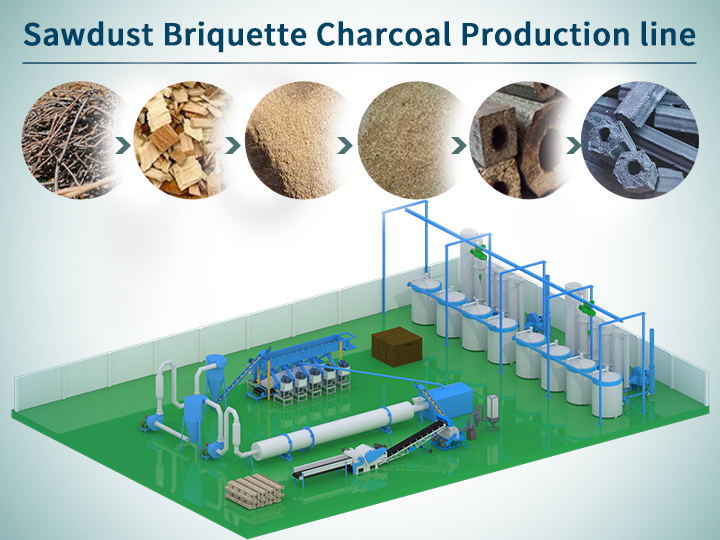

Zusammenfassend bieten Kasten-Trocknungsräume nicht nur Vorteile wie Energieeffizienz, Umweltfreundlichkeit, einfache Bedienung und breite Anwendbarkeit, sondern sind auch unverzichtbare Geräte in Produktionslinien für Shisha-Holzkohle und andere Produkte. Sie gewährleisten effektiv die Formgebung und Qualität der fertigen Holzkohle und helfen Herstellern, Effizienz und Rentabilität zu steigern.

Wenn Sie den Bau oder die Erweiterung einer Holzkohleproduktionslinie in Erwägung ziehen, klicken Sie bitte auf den obigen Link, um weitere professionelle Lösungen zu erhalten. Kontaktieren Sie uns sofort, um maßgeschneiderte Lösungen und Angebote zu erhalten – unser Team wird Ihnen umfassende Unterstützung bieten!