Der Sägemehlbrikettkohle ist eine neue Art von Holzkohle, die aus Biomasseholzmaterialien hergestellt wird. Im Vergleich zu traditioneller Holzkohle hat sie die Vorteile einer regelmäßigen Form, Flammenbeständigkeit und keiner Staubexplosion. Nach zehn Jahren kontinuierlicher Innovation und Verbesserung verfügt die gesamte Brikettkohleproduktionslinie über eine angemessene Ausrüstungsquotenverbindung, die die Arbeitskosten erheblich senken und die Produktionseffizienz verbessern kann.

Darüber hinaus kann diese Brikettkohle-Produktionslinie gemäß den Anforderungen der Kunden angepasst werden. Sie kann als vollautomatische Produktionslinie oder als halbautomatische Produktionslinie konzipiert werden, die von der Mehrheit der Holzkohlenhersteller weithin gelobt wurde.

Im Gegensatz zur Holzkohleproduktionslinie (verwandter Artikel: Holzkohleherstellung Produktionslinie) verwendet diese Linie die Verarbeitungsreihenfolge erst Formen und dann Verkohlung. Daher ist nach dem Sägemehlbrikettierungsbetrieb im obigen Video erneut eine Verkohlungsausrüstung erforderlich, um die endgültigen Holzkohlebriketts herzustellen.

Arbeitsablauf der Holzhackschnitzel-Brikett-Holzkohle-Herstellungslinie

Die Brikettkohle-Produktionslinie umfasst hauptsächlich vier große Schritte: Zerkleinern, Trocknen, Brikettieren und Karbonisieren. Die Rohstoffe, die in der Sägemehl-Brikettmaschine verwendet werden, müssen eine Feinheit von maximal 6 mm aufweisen, und der Feuchtigkeitsgehalt sollte zwischen 8 % und 12 % liegen. Daher müssen die Materialien zuerst zerkleinert und getrocknet werden.

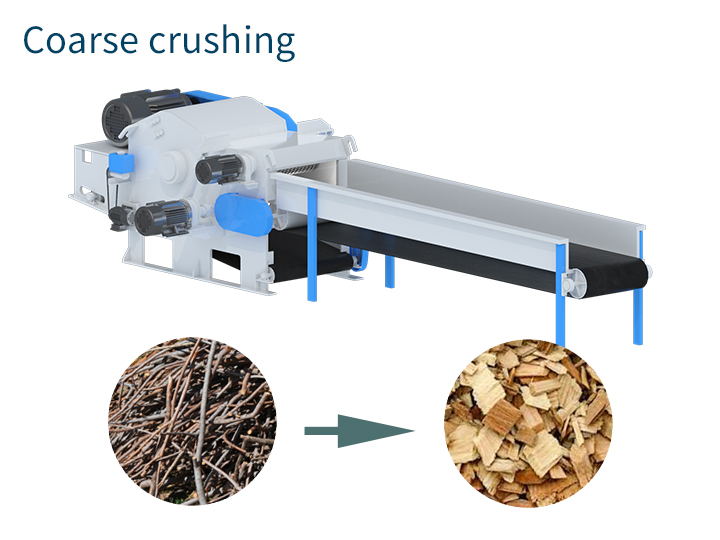

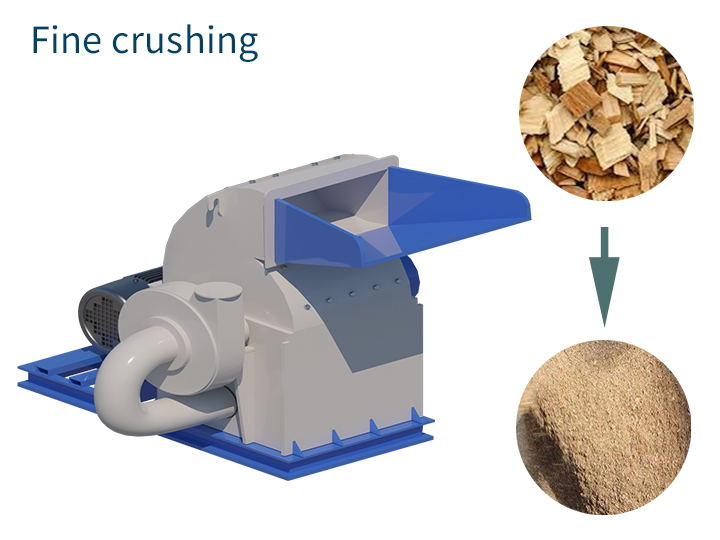

- Zerkleinerung: Der Zerkleinerungsprozess umfasst hauptsächlich zwei Prozesse: Grobzerkleinerung und Feinzerkleinerung. Die Rohstoffe müssen in 3-6 mm Holzstaub pulverisiert werden.

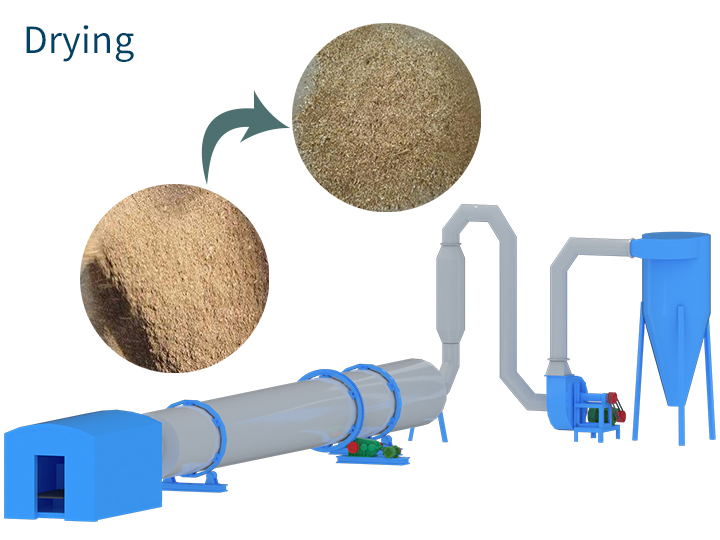

- Trocknung: Der Trockner dient hauptsächlich dazu, die Feuchtigkeit im Material zu reduzieren und die Feuchtigkeit je nach Materialtyp auf 8%-12% zu senken. Die getrockneten Materialien müssen vor dem Brikettieren abgekühlt werden.

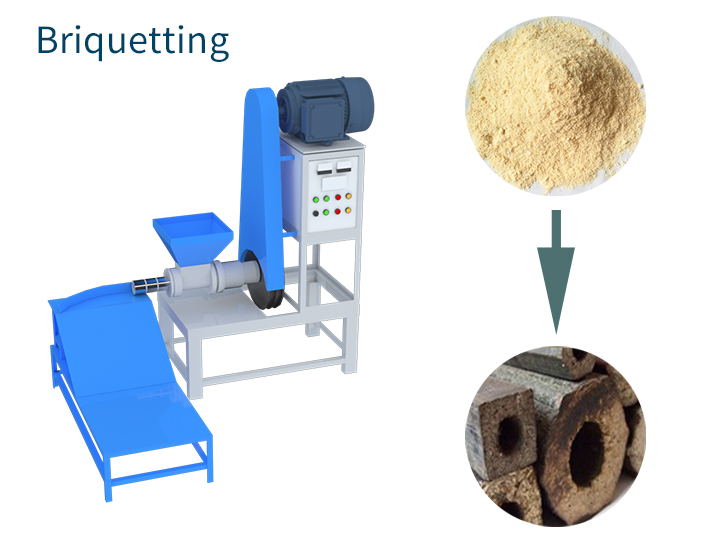

- Brikettierung: Diese Maschine formt das Material unter hohen Temperaturen und Druck in Brikettstäbe unterschiedlicher Formen und Längen.

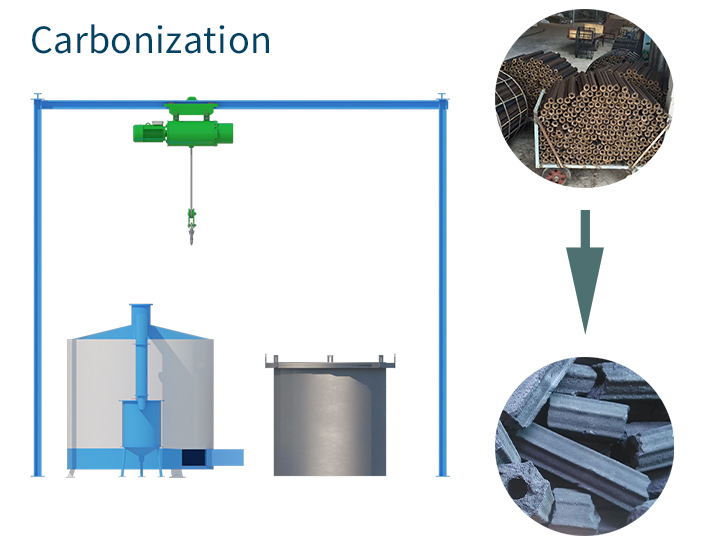

- Karbonisierung: Das Holzschnitzelbrikett wird unter den Hochtemperaturbedingungen des Kohlenstoffisierungsofens karbonisiert.

Hauptkomponenten der Brikett-Holzkohle-Produktionslinie

Die Produktionslinie für Brikettkohlemaschinen umfasst den Holzzerkleinerer, den Sägemehl-Trockner, die Brikettpressmaschinen, die Karbonisierungsöfen und andere Hilfsgeräte.

Holzzerkleinerer

Der Hauptzweck dieser Phase besteht darin, große Holzstücke oder holzige Rohstoffe in geeignete Partikelgrößen zu zerbrechen, um sich auf den anschließenden Prozess der Brikettkohleproduktion vorzubereiten. Durch das Zerkleinern wird die Oberfläche des Holzes vergrößert, was die nachfolgenden Verarbeitungsschritte wie Verkohlung und Formgebung begünstigt, um die Kohleproduktion und -qualität zu verbessern.

Rotations-Trockner

Der Luftstromtrockner wird verwendet, um die feuchten Materialien mit dem Hochtemperatur-Luftstrom zu mischen und schließlich das Wasser von dem Rohmaterial durch den Separator zu trennen.

Rohmaterial gelangt durch den Eingang in das Rohr und wird durch den Windventilator und heiße Luft in den Zyklon gepumpt.

Die getrockneten Materialien werden aus dem Zyklon freigesetzt, und die Abwärme sowie der Wasserdampf werden aus den Sandklonen abgeführt. Im Allgemeinen wird es zum Trocknen von Sägemehl in der Holzverarbeitung und zum Trocknen von Pellets in der Biomassepelletproduktion verwendet.

Sägemehl-Brikettmaschine

Die Biomasse-Sägespäne-Brikettmaschine kann Holzspäne und -späne, Reis- und Erdnussschalen, Bagasse und andere Holzmaterialien unter hohen Temperatur- und Druckbedingungen in hohle Stäbe aus festem Brennstoff (Biomasse-Holzkohle) umwandeln.

Diese Maschine besteht hauptsächlich aus dem Motor, dem Steuerkasten & Bedienfeld, dem Einlass, dem Formzylinder, dem Heizsystem usw.

Kohlenstoffisierungsofen

Die Karbonisierung von Holzmaterialien, die Kohlenstoff enthalten, unter Hochtemperaturbedingungen im Ofen. Unser neuer Typ von Karbonisierungsofen besteht hauptsächlich aus der Verbrennungskammer, der Karbonisierungsverkleidung, der Abgasbehandlungsanlage, dem Abwärmenutzungssystem und dem Kransystem.

Heißsiegelfolie Verpackungsmaschine

Schließlich können Sie wählen, ob Sie diese Verpackungsmaschine je nach Bedarf verwenden möchten, die Schrumpffolie verwenden, um die Kohle fest zu verpacken, um sie vor der externen Umgebung zu schützen, das Aussehen und die Qualität des Produkts zu verbessern und den Transport und die Lagerung zu erleichtern.

Rohstoffe für die Briquettenkohleproduktion

Die Rohstoffe der Brikettkohleproduktionslinie sind vielfältig und umfassen Stämme, Äste, Bambus, Späne, Kokosnussschalen, Reisspelzen, Erdnussschalen, Erntereste und andere Holzmaterialien.

Präsentation und Anwendung der Fertigprodukte

Die fertigen Kohlenbriketts, die durch eine Brikett-Kohleproduktionslinie verarbeitet werden, sind ein häufig verwendeter Biomassebrennstoff zum Heizen, Kochen und für andere Energiebedarfe. Aufgrund ihrer hohen Verbrennungseffizienz und des hohen Heizwerts werden sie in Haushalten, in der Industrie und in ländlichen Gebieten weit verbreitet eingesetzt.

Anzeige der Brikettkohleproduktionslinie

Wenn Sie an unseren Produkten der Brikettkohle-Produktionslinie interessiert sind oder Fragen oder Bedürfnisse zur Kohlenproduktion haben, zögern Sie bitte nicht, unser professionelles Team zu kontaktieren. Gleichzeitig heißen wir Sie herzlich willkommen, unsere Fabrik zu besuchen. Wir bieten vielfältige Lösungen und maßgeschneiderte Ausrüstungen, um Ihren Produktionsbedürfnissen gerecht zu werden.