바이오매스 가스화는 저칼로리 바이오매스 에너지원의 사용으로, 특정 반응 조건 하에서 산화환원 반응을 거쳐 수소 및 일산화탄소와 같은 가연성 가스를 생성합니다. 이 반응으로 생성된 가스는 열 에너지를 제공하거나 전기를 생산하는 데 직접 사용할 수 있습니다.

바이오매스 에너지는 무엇인가요?

바이오매스 에너지의 원천은 태양 에너지입니다. 바이오매스 에너지는 미생물, 식물 및 동물이 광합성을 통해 축적한 에너지입니다. 바이오매스 에너지의 원천은 매우 다양합니다. 농작물의 짚, 나무 가공 폐기물, 동물 분뇨, 도시 가정 폐기물, 고무, 플라스틱 폐기물과 같은 산업 폐기물 등이 일반적인 바이오매스 에너지입니다.

바이오매스 에너지의 특징은 무엇인가요?

- 환경 보호: 우선, 원자재는 모든 종류의 폐기물로, 일부 폐기물의 처분 문제를 해결합니다. 둘째, 산화-환원 반응 후 생성된 가스는 일산화탄소(CO)와 수소(H)입니다.2), 메탄(CH4), 폴리아세틸렌(CmHn) 및 기타 연료 가스는 환경에 오염을 일으키지 않습니다.

- 재생 가능 에너지: 바이오매스 에너지는 식물과 동물의 광합성을 통해 다시 생산될 수 있습니다. 이는 태양 에너지, 수력 에너지, 풍력 에너지 등과 함께 재생 가능 에너지에 속합니다.

- 총 금액의 풍부함: 바이오매스 에너지는 지구에서 네 번째로 큰 에너지원으로, 다양한 출처를 가지고 있습니다. 통계에 따르면, 지구에서 매년 생산되는 바이오매스 에너지는 인류가 소비하는 에너지의 약 10배에 달하지만, 인류가 이러한 에너지를 활용하는 비율은 3%도 되지 않습니다.

- 낮은 생산 비용: 바이오매스 폐기물 재활용 비용이 낮기 때문에 바이오매스 에너지를 사용하여 전기를 생산하는 비용은 매우 낮으며, 0.2-0.3 RMB/Kw.H에 가깝습니다. 이는 석탄을 사용하여 전기를 생산하는 비용의 60%-70%에 해당합니다.

위의 바이오매스 에너지의 특성으로 인해 점점 더 많은 국가들이 이러한 에너지의 사용에 주목하기 시작했습니다. 바이오매스 에너지를 사용하여 전력을 공급하거나 전기를 생산하는 것은 미래의 발전 추세입니다.

바이오매스 가스화 소개

불완전 연소와 가스화기에서의 바이오매스 에너지의 산화-환원 반응 후, 일련의 가연성 가스가 생성됩니다. 이 과정을 바이오매스 에너지 가스화라고 합니다.

작업 과정

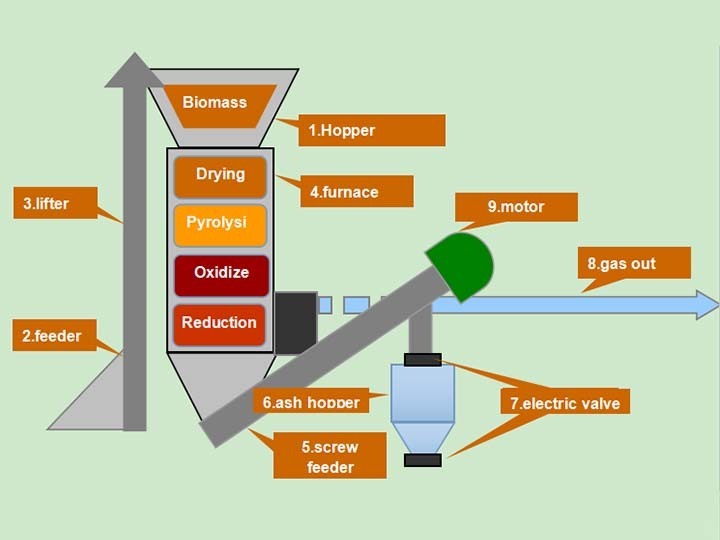

건조 → 열분해 → 산화 → 환원 → 정화 → 연료 가스의 연소 및 활용

상대 장치

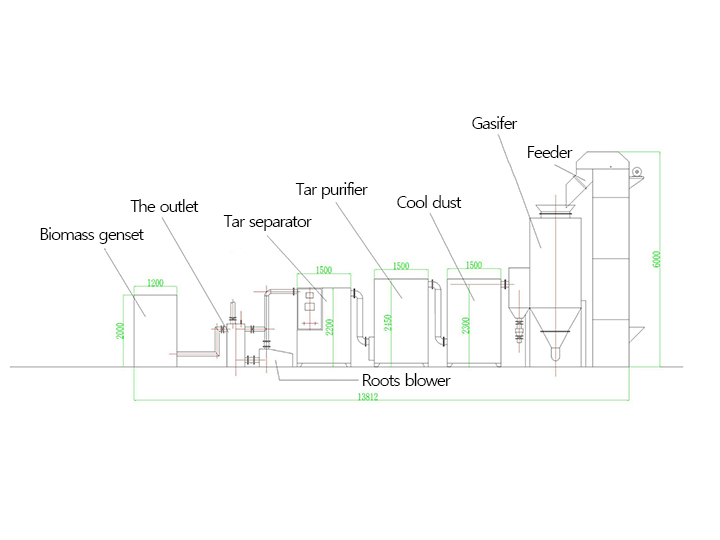

가스화기-냉각 집진기-타르 정화기-타르 분리기-내연기관 발전기/보일러 등.

가스화 과정

가스화기는 주로 공기층, 건조층, 열분해층, 산화층, 환원층의 다섯 개 층으로 나뉩니다.

바이오매스 재료가 가스화로에 들어가면 건조되고 가열됩니다. 온도가 계속 상승함에 따라 휘발성 물질이 고온에서 침전되고 열분해 반응을 겪습니다. 열분해 가스와 카바이드가 반응하여 수증기와 이산화탄소를 생성합니다. 동시에 생성된 열은 환원 반응의 흡열 환원 및 타르의 열분해에 사용되어 최상의 열 활용을 달성할 수 있습니다.

가스화기의 바닥에 있는 나선형 컨베이어에서 먼지가 배출되고, 배기 포트에서 가스가 배출됩니다. 이때 얻어진 가스는 직접 생산에 사용될 수 없으며, 사용되기 전에 가스 내부의 먼지와 타르를 제거하기 위해 정화 및 필터링이 필요합니다.

정화 과정

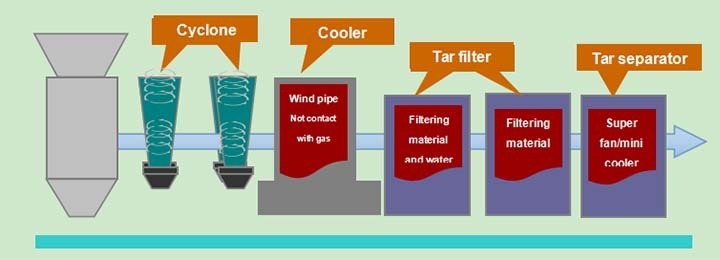

- 불순물 제거 장치: 전체 장비 세트는 불순물 제거의 좋은 효과를 보장하기 위해 6세트의 사크론이 장착되어 있습니다.

- 냉각 장치: 합성가스는 차가운 공기를 통과하면서 그 안의 물과 타르를 응축시킵니다. 이 과정에서 합성가스는 기계 내부의 공기와 직접 접촉하지 않고 기계 내부의 공기 덕트를 통과합니다.

- 타르 필터: 타르 필터는 물에 담긴 네 개의 타르 제거기로 구성되어 있습니다.

- 타르 분리기: 이 기계는 냉각 장치를 포함하고 있어 물과 타르를 응축시킬 수 있으며, 이후 건식 여과 방법을 사용하여 원심 여과를 통해 타르를 배출합니다.

- 필터: 필터 내부에는 타르와 수증기의 최종 필터링을 위한 활성탄과 스테인리스 스틸 필터 스크린이 포함되어 있습니다.

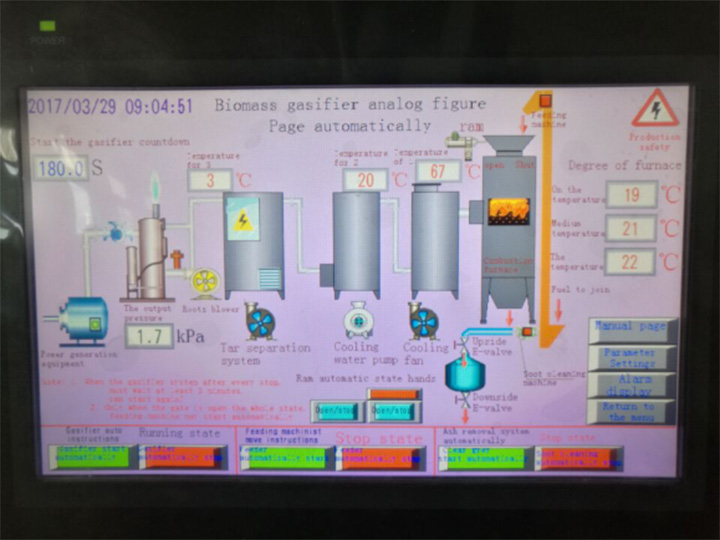

- 루츠 블로워: 루츠 블로워는 전체 가스화 과정과 정화 시스템의 전원입니다. 전체 생산 과정에서 루츠 블로워의 역할은 기계를 음압 상태에서 작동하게 하는 것뿐만 아니라, 가스화 반응이 완전히 이루어지도록 하여 너무 많은 이산화탄소가 발생하지 않도록 하는 것입니다.

원자재에 대한 바이오매스 가스화 요구사항

- 원자재의 크기: 바이오매스 입자 또는 블록의 크기는 30mm를 초과해서는 안 됩니다.

- 원자재의 습도: 수분 함량은 ≤20% 여야 합니다.

비디오: 200kw 바이오매스 가스화 발전소

바이오매스 가스화 라인의 매개변수

가스화기 KX-300SA의 매개변수

| 합성가스 출력 | 300m3/h | 합성가스 열량 | 1000-1200 kcal/m3 |

| 연료 소비량 | 150kg/h | 전원 공급 | 380V 50Hz/60H |

| 가스화 효율 | >72% | 가스화기 출력 | 18kw |

| 매칭 엔진 | 100kw | 원자재 | 길이 크기는 < 30mm, |

| 요구 사항 | 습기 함량 < 20% | ||

| 인증서 | CE | 원산지 | 중국 정저우 시 |

| 설치 크기 | (길이 × 너비 × 높이) 14m×3.5m×5.16m | ||

가스화기 공급 범위

| 번호 | 이름 | 부품 | 번호 | 비고 |

| 1 | 로켓 본체 부품 | 로켓 본체 | 1 | 가스화기 반응기 |

| 충전기 | 1 | 원자재 운송 | ||

| 충전 인터페이스 | 1 | 매칭 | ||

| 스크류 재 ash 배출기 | 1 | 기계식 재 제거 | ||

| 재 호퍼 | 1 | 탄소 재 임시 저장소 | ||

| 전기 나비 밸브 | 4 | 재 제거기 폐쇄 밸브 | ||

| 비디오 관찰자 | 1 | 가스화기 챔버에서의 연소 관찰 | ||

| 화로 보호판 | 1 | 안전 보호 | ||

| 수준계 | 2 | 로스터 챔버 내 원자재의 수와 재받침대의 탄소 재의 양을 제어합니다. | ||

| 온도 센서 | 3 | 급여 및 재 제거 제어 | ||

| 철 원뿔 | 1 | 보조 재료 | ||

| 2 | 더스터 | 사이클론 집진기 | 6 | 합성가스 탈진 |

| 공기 냉각 팬 | 1 | 냉각 | ||

| 온도 센서 | 1 | 탐지 온도 | ||

| 3 | 냉각기 | 냉각기 | 1 | 가스 냉각 |

| 팬 | 1 | 냉각 | ||

| 4 | 타르 정화기 | 네 세트의 타르 제거기와 하나의 수냉식 냉각 가스 세트를 포함하고 있습니다. | 1 | 타르 제거 |

| 냉각기 | 1 | 순환수 냉각 | ||

| 수중 순환 펌프 | 1 | 냉각수 순환 | ||

| 온도 센서 | 1 | 탐지 온도 | ||

| 5 | 타르 필터 | 가스 냉각 장치 | 1 | 냉각 합성가스 |

| 타르 원심 분리기 | 1 | 타르 분리 | ||

| 건조 필터 | 1 | 여과된 타르 | ||

| 온도 센서 | 1 | 탐지 온도 | ||

| 6 | 루츠 블로워 | 루츠 블로워 | 1 | 바이오매스 가스화에 전력 공급 |

| 압력 변환기 | 1 | 루트 블로워 제어 | ||

| 고무 소프트 연결 | 2 | 충격 흡수 및 소음 감소 | ||

| 7 | 폴리테트라플루오로에틸렌 나비 밸브 | 3 | 합성 가스의 운반 제어 | |

| 8 |

가스 배급기 | 세 개의 건식 필터 세트 포함 | 1 | 합성가스 여과 |

| 토치 | 1 | 합성가스 품질 감지 | ||

| 9 | 제어 캐비닛 | PLC | 1 | 장비 운영 제어 시스템 |

| 10 | 연결 파이프 | 용접 | 가스화기 연결 | |

| 11 | 볼트 및 석면 패드 | 가스화기 커넥터 및 씰 | ||

| 12 | 홀드올 | 1 | 장비 설치 도구 |

발전기 공급 범위

| 모델 번호 (엔진 유형) | 118D12TL-2 |

| 기본 전력 | 100KW |

| 정격 속도 (r/min) | 1500/1800 |

| 정격 주파수 | 50Hz / 60Hz |

| 정격 전압 | 400V/230V |

| 상 | AC 3상, 4선 |

| 전압 안정성 | ≤±1% |

| 전압 과도 | ≤-10%–+20% |

| 전압 안정 시간 | ≤3초 |

| 열 소비 | ≤11mj/Kw.h |

| 윤활유 소비 | ≤1.0g/Kw.h |

| 엔진 용량 | 151.8 L |

| 실린더 번호 | 6-V |

| 실린더 보어 | 128mm |

| 스트로크 | 152mm |

| 시동 시스템 | DC 24V 전기 모터 |

| 냉각 방법 | 워터 쿨러 |

| 윤활제 방법 | 수동 및 비행 윤활제 |

| 격리 등급 | H |

| 보호 | IP23 |

| 발전기 | 중국 스탬포드 |

| 역률 | 0.8 지연 |

| 자극 방법 | 브러시리스 |

| 색상 | 당신의 선택 |

| 인증서 | ISO 9001:2008, CE |

| 보증 | 1년 또는 1000운전시간 중 먼저 도래하는 것 |

| 유형 | 열기 |

| 제어 시스템 | 자동 경고 시스템 |

| 크기 | 2850x1100x1750mm |

| 무게 | 2350kg |

성공적인 사례

러시아의 고객이 우리 공장을 방문하여 기술 직원과 심도 있는 교류를 가졌습니다.