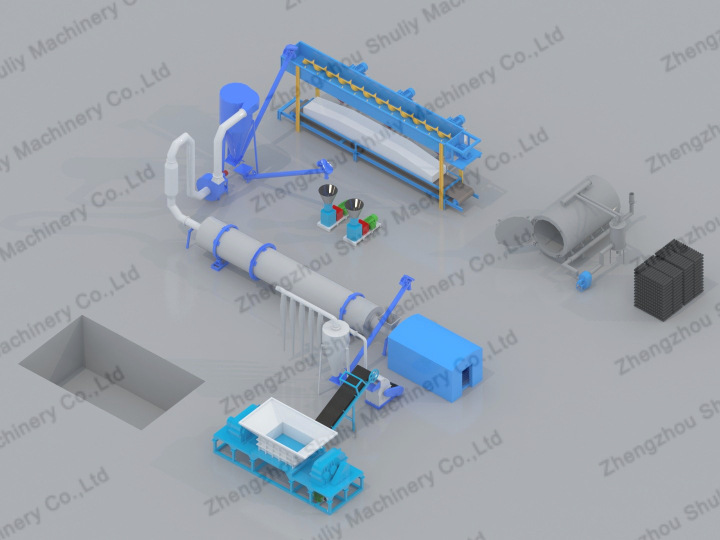

Carvão é o produto da queima incompleta da madeira e é um combustível ambientalmente amigável. Existem duas maneiras principais de processar o carvão, a ordem de carbonização e moldagem podem ser trocadas. Ambas as vias podem produzir carvão de alta qualidade. A empresa Shuliy machines de carvão tem exportado por dez anos e possui um conjunto de equipamento de produção de carvão com diferentes saídas e tipos de fornos de carbonização.

Tipo um: primeira carbonização e depois formação

A primeira carbonização é carbonizar materiais como pó de carvão, serragem, pó de madeira e bambu, pó de carvão de bambu, borras de vinho, bagaço e outros materiais residuais. Alguns, como galhos, segmentos de árvore, palha, etc., precisam ser carbonizados e depois triturados, para alcançar 5-8MM, podendo ser prensados em varas de carbono pela máquina de moldagem de pó de carbono. Os produtos de carbono embalados dessa forma são carvão acabado e não precisam ser carbonizados novamente.

Tipo dois: primeiro moldagem e depois carbonização

As matérias-primas utilizadas são geralmente cascas de amendoim, espigas de milho e palha de arroz, que são trituradas primeiro e, em seguida, secas após a trituração do material. Esses bastões de carbono são produtos semi-acabados, ou seja, bastões crus. Em seguida, vem a etapa final de carbonização, para que os bastões de carbono possam se tornar carbono de lascas de madeira.

Vantagens dos dois métodos de produção de carvão

Os produtos acabados podem ser feitos em várias formas, como carvão de água e fumaça e carvão em favo de mel, e o carvão triturado pode ser processado novamente sem desperdício de matérias-primas. A produtividade do carvão é alta. O carvão é primeiro moldado e depois carbonizado de uma segunda maneira, que é fácil de operar e consome menos energia. Ambas as duas maneiras de produção de carbono estão disponíveis, e o carvão processado é muito bom. Você pode escolher a máquina de acordo com as necessidades reais da sua produção.