Машина для производства брикетов из угольных шариков для барбекю - это формировочное оборудование, которое эффективно прессует сырьевые материалы, такие как угольный порошок, древесный уголь, минеральный порошок, коксовый порошок, биомассовые отходы и т. д. С помощью сменного формовочного ролика на 360° (с точностью ±0,1 мм) сырьевые материалы могут быть прессованы в 12 индивидуальных форм шариков, таких как круглые, овальные или в форме подушки.

Скорость формирования угольного шара составляет ≥98%, прочность превышает 90 кг/см², а теплотворная способность достигает 7500 ккал/кг. Он широко используется в металлургии, химической промышленности, электроэнергетике, энергетике, переработке топлива и других отраслях.

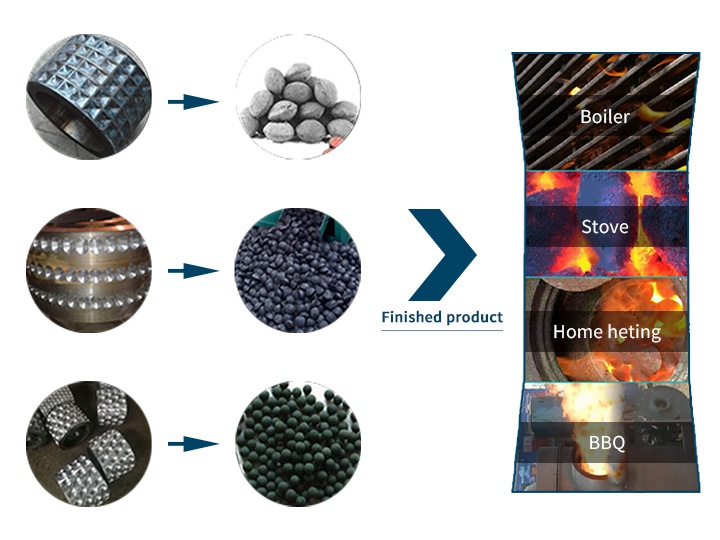

По сравнению с традиционным древесным углем, сформированный уголь для барбекю имеет преимущества: не дымит, нетоксичен, без запаха, имеет высокую теплотворную способность, легко зажигается, легко транспортируется и хранится и т.д. Это идеальный выбор топлива для экономии энергии и охраны окружающей среды.

Независимо от того, используете ли вы его для производства угля для барбекю или для пакетной переработки промышленных топлив. Мы предлагаем различные модели и формы форм, чтобы удовлетворить потребности в различном производстве и индивидуальной настройке форм, помогая вам эффективно вести бизнес по производству угольных шариков.

Основная структура машины для брикетирования угольных шариков

- Часть подачи: она состоит из бункера и шнекового устройства подачи, которое отвечает за равномерную и количественную подачу материалов между прессующими роликами. Шнековый питатель приводится в движение электромагнитным мотором с регулируемой скоростью, что обеспечивает стабильную подачу материала и гарантирует качество формирования шариков.

- Часть трансмиссии: включает в себя мотор, треугольный ремень, редуктор, открытое зубчатое колесо и так далее. Мощность передается на главный вал через муфту, а затем приводит в движение ведомый вал для синхронизации работы и реализации действия прессования шариков.

- Формующая часть: она состоит из пары равных по размеру пресс-роликов с регулярно расположенными полусферическими отверстиями для формовки на поверхности. Оснащена гидравлическим защитным устройством, которое при столкновении с твердыми предметами или перегрузке может автоматически сбрасывать давление, чтобы защитить пресс-ролик от повреждений.

Эта конструктивная схема обеспечивает высокую эффективность, стабильность и безопасность машины для производства угольных брикетов, что является основным гарантией достижения высококачественного формования древесного угля для барбекю.

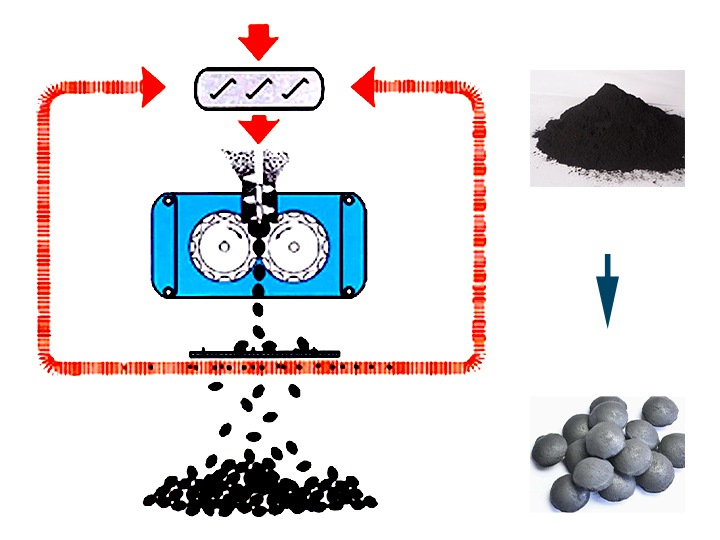

Принцип работы машины для прессования древесного угля

Основная часть машины для производства угольных брикетов состоит из пары вращающихся валов одинакового размера, с множеством полусферических гнезд одинакового размера, регулярно расположенных на поверхности.

- Обработанный материал будет поступать через загрузочный порт и сжиматься в полусферические гнезда с обеих сторон под действием своей силы тяжести и давления валиков с обеих сторон.

- Полусферические гнезда с обеих сторон сливаются в полную сферу, а сырьевые материалы внутри будут постепенно сжиматься и в конечном итоге образуют угольный брикет.

- При дальнейшем движении вала сформированный угольный шар падает из разгрузочного порта.

Преимущества машины для производства угольных брикетов

- Горит дольше и экономит больше угля: после прессования угольного порошка в шары он горит дольше и эффективнее, чем обычный уголь.

- Защита окружающей среды и энергосбережение: прессованные брикеты не дымят, не имеют запаха и обладают высокой теплотворной способностью, подходят для барбекю и отопления, чистые и энергосберегающие.

- Автоматическое защитное оборудование: имеется гидравлическое защитное устройство; если машина контактирует с твердыми предметами, она может автоматически разгружаться, не повреждая пресс-вал.

- Более плавная подача: специально разработанная система подачи может прессовать даже легкий порошок (например, древесный уголь) в шары, что затрудняет блокировку материала.

- Система передачи более надежна: передающее устройство закрыто, в него не попадает зола, меньше шума, меньше износа, дольше срок службы.

- Стиль прессования можно настроить: его можно сделать в форме круглого шара, подушки, яйца и других форм, а также можно настроить по размеру и стилю в соответствии с требованиями клиентов.

Требования к сырью и применение брикетов из древесного угля

Машина для прессования угольных брикетов может использоваться для прессования угольной пыли, железной пыли, коксующегося угля, алюминиевой пыли, железных опилок, оксида железа, угольной пыли, шлака, гипса, хвостов, осадка, каолина, активированного угля и коксующейся пыли и т.д.

Мелкость материала должна быть ниже 3 мм, а содержание влаги должно составлять 8-12%. Связующее или другие добавки (например, десульфуризованные) должны быть подготовлены пользователями в зависимости от типа угля и эксплуатационной среды. Готовая продукция широко используется в огнеупорной, энергетической, металлургической, химической, энергетической, транспортной, отопительной и других отраслях.

Разные формы машины для формовки угольных шариков

В зависимости от формы и размера угольных шариков для гриля, которые нужны каждому, мы подготовили разные формы на выбор. Вы также можете сообщить нам о готовом продукте, который вы хотите, и мы можем его настроить.

Демонстрация машины для брикетов из угольных шариков для барбекю

Технические параметры машины для экструзии угольных шаров

Машина для производства брикетов из угольных шариков для барбекю демонстрирует передовые технологии и отличные характеристики, а ее параметрическая информация соответствует потребностям пользователей во всех аспектах. Высокая производственная мощность и регулируемый размер шариков обеспечивают ей отличную гибкость и эффективность производства в процессе производства угля для барбекю.

| Модель | Мощность | Энергия | Ширина ролика | Диаметр рулона |

| SLYQJ-360 | 2т/ч | 7.5 кВт | 250мм | 360мм |

| SLYQJ-400 | 4т/ч | 11-15кВт | 280мм | 400мм |

| SLYQJ-500 | 6т/ч | 18.5-22кВт | 300мм | 500мм |

| SLYQJ-650 | 10т/ч | 20-30кВт | 336мм | 650мм |

| SLYQJ-750 | 15т/ч | 45кВт | 400мм | 750мм |

| SLYQJ-850 | 25т/ч | 75 кВт | 500мм | 850мм |

| SLYQJ-1250 | 35т/ч | 130кВт | 650мм | 1250мм |

Связанное видео машины для брикетирования угольных шариков

Также у нас есть другие машины для производства древесного угля на выбор. Если вас заинтересует, вы можете перейти по ссылке: Гидравлическая и механическая машина для производства угля для кальяна и Машина для производства угля в виде сот | Машина для производства угольных брикетов.

Чтобы узнать больше о превосходной производительности и технических преимуществах машины для брикетирования угля для барбекю, мы настоятельно рекомендуем вам активно связаться с нами. Наша профессиональная команда с радостью предоставит вам подробную информацию о продукте, индивидуальные предложения и решения. Кроме того, мы тепло приглашаем вас посетить наш завод, чтобы ознакомиться с эффективной работой и передовыми технологиями машины для брикетирования угля для барбекю.