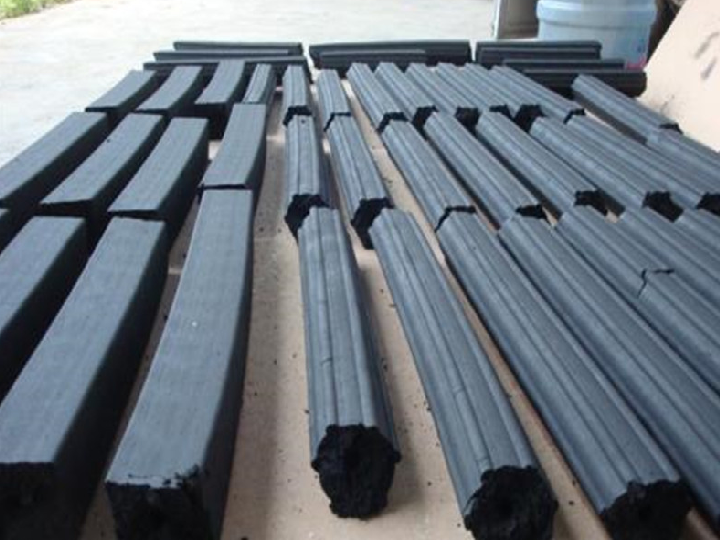

Die Holzkohle-Extruder-Maschine ist eine Maschine, die pulverisierte Kohle in verschiedene Streifen umwandeln kann. Es handelt sich um eine Art Ausrüstung zur Formung von Kohlerohren. Es gibt verschiedene Modelle von Maschinen zur Formung von Kohlerohren, die sowohl für die Einzelproduktion als auch für große Fabriken geeignet sind, um Kohlerohre herzustellen.

Der Prozess des Abschlusses eines Geschäfts mit einem Kunden der Holzkohle-Extruder-Maschine.

Wir haben eine Anfrage von einem Kunden bezüglich der Holzkohle-Extruder-Maschine erhalten. Der Kunde kommt aus Senegal. Hier sind wir sehr neugierig zu fragen, warum der senegalesische Kunde die Kohlenstabmaschine ins Vereinigte Königreich versenden möchte? Nach dem Gespräch stellte ich fest, dass der aktuelle Kunde im Vereinigten Königreich Geschäfte macht, daher muss die Maschine ins Vereinigte Königreich versendet werden.

Verstehen Sie die Situation der Kunden der Kohlenbrikettmaschine.

Zuerst verstehen wir die Bedürfnisse der Kunden, die Form und Art der Kohlerohre, die wir verarbeiten möchten, und erst wenn wir die Produktionssituation der Kunden in Senegal verstehen, können wir geeignete Kohlerohmaschinen empfehlen. Der senegalesische Kunde ist ein lokaler Hersteller von Kohlerohren. Er ist seit mehreren Jahren in der Produktion von Kohlerohren tätig, aber die Ausbeute ist nicht groß. Ich denke, er ist optimistischer hinsichtlich der Produktion und Verarbeitung von Kohlerohren. Daher möchten wir eine Holzkohle-Extrusionsmaschine kaufen, um die Ausbeute zu erhöhen. Wir möchten dem Kunden die Modelle mehrerer Kohlerohmaschinen, die derzeit von der Fabrik produziert werden, zusenden. Die Maschine mit der minimalen Ausbeute hat eine Leistung von 500 kg/h, und die Maschine mit der maximalen Ausbeute hat eine Leistung von 3000 kg/h. Wir werden die sortierten Informationen dem Kunden zur Auswahl zusenden.

Stellen Sie das Modell der Holzkohle-Extruder-Maschine der Shuliy-Firma vor.

Der Kunde sagte, dass er tagsüber arbeiten muss, weshalb es langsam ist, auf die Nachricht zu antworten, und wir verstehen das sehr gut. Der Kunde sagte, dass die Verarbeitung von Kohlerohren weiterhin jeden Tag durchgeführt wird. Zu Beginn des Gesprächs wollte der Kunde eine Maschine des Modells 180 kaufen, benötigte jedoch keinen Cutter und kein Förderband. Der Kunde plante, es von Hand zu schneiden, aber das Problem beim manuellen Schneiden ist, dass die Längen der geschnittenen Kohlerohren unterschiedlich sind, was sehr unschön aussieht. Wir verstehen, dass die Kunden Kosten sparen wollen, aber das ist nicht förderlich für die langfristige Produktion.

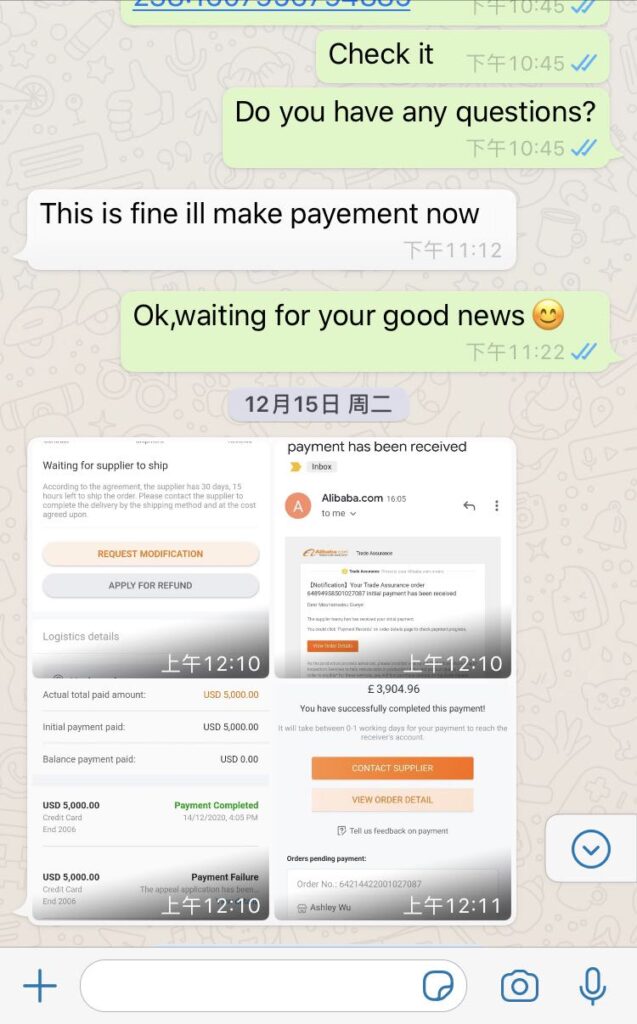

Einen Vertrag mit einem Kunden der Holzkohle-Extruder-Maschine unterzeichnet.

Nach der Analyse empfehlen wir den Kunden weiterhin eine Maschine mit geringem Output, aber mit einer Schneidfuktion. Wir haben Maschinenbilder und Arbeitsvideos gesendet, und der Kunde hat nach der Lieferzeit gefragt. Unsere Fabrik hat Halbfertigerzeugnisse der Maschine, und sie kann innerhalb von 3-5 Tagen nach Vertragsunterzeichnung mit dem Kunden versendet werden, und das CE-Zertifikat wird beigefügt.

Modell der Holzkohle-Extruder-Maschine

| Modell Name | MBJ140 | MBJ180 | MBJ210 | MBJ300 | MBJ400 |

| Produktionskapazität | 500kg/h | 1000kg/h | 1500kg/h | 2000kg/h | 3000kg/h |

| Formungsspezifikationen | Durchmesser 20-40 | Durchmesser 20-60 | Durchmesser 20-80 | Durchmesser 20-80 | Durchmesser 20-80 |

| Spindeldrehzahl | 46-60 U/min | 39-60 U/min | 35-60 U/min | 35-60 U/min | 35-60 U/min |

| Anzahl der spiralförmigen Klingen | 4 | 4 | 4 | 4 | 4 |

| Motor | Y160m-4 11kW | Y180m-4 18,5kW | Y200L-4 30kW | Y225s-4 37kW | Y315m-4 160kW |

| Reduzierer | ZQ350 | ZQ400 | ZQ500 | ZQ650-750 | ZQ850 |

| lager | 7511, 211, 210, 1305 | 7614, 314, 313, 1206 | 7619, 319, 318, 1206 | 32320, 320, 319, 1207 | 32322, 322, 321 |

Warum wählen Kunden Shuliy?

1. Das Zertifikat ist vollständig. Ein CE-Zertifikat ist erforderlich, wenn die Maschine zum Hafen im Vereinigten Königreich verschifft wird. Schulley kann ein professionelles Zertifikat bereitstellen.

2. Informationen rechtzeitig senden. Kunden haben in der Regel vielbeschäftigte Arbeitszeiten, und es bleibt nicht viel Zeit für die Kommunikation. Wir lösen die Fragen der Kunden jedes Mal zeitnah und senden die Informationen zur Kohlenstabmaschine, die von den Kunden benötigt werden.

3. Die Maschine ist von guter Qualität und hat vollständige Modelle. Wir bieten Maschinen an, die den Bedürfnissen der Kunden entsprechen.